Eyes123456's blog

Three-dimensional fiber laser cutting machine consists of a dedicated fiber laser cutting head, high-precision capacitive tracking system, fiber laser and industrial robot system, the different thickness of the metal plate multi-angle, multi-directional flexible cutting advanced cutting equipment. High flexibility, especially for small quantities of three-dimensional sheet metal cutting; to ensure cutting quality, making cutting more convenient and easier to operate; configuration intelligent robot, enabling three-dimensional cutting, easy operation, high intelligence, to ensure the equipment High speed, high precision, high reliability.

Material Scope: Suitable for stainless steel, carbon steel, alloy steel, silicon steel, galvanized steel, nickel-titanium alloy, Inconel, aluminum, aluminum, titanium, copper and other metal materials. Industry Applications: Three-dimensional high power laser cutting machine is widely used in aerospace, automotive steamship, machinery manufacturing, metal processing services and other manufacturing industries. The automobile industry is widely used. Sheet metal covers for automobile parts include the cover, the rear lid box, the water tank shelf, the bumper, the fender, the door and the ingot beam of the chassis part, the control arm, the rear axle and the like.

Laser processing as an advanced material cutting method, has been increasingly accepted by sheet metal producers. With the continuous improvement of computer control technology and optical technology, people are expecting more and more for their processing ability. This expectation is not only an expectation of being able to cut, but also of cutting well and cutting fast. Of course, can give the answer can not do without the performance of the processing machine, while being processed material merits also have a direct impact on results.

With laser processing as the main cutting tool is accepted, 25mm below the ordinary steel laser professional materials as a standard material. Cutting section improvement program An important factor for the improvement of the cutting section of carbon steel is the control of the heat input to the sheet and sufficient combustion of the laser irradiated portion. Glossy cutting technology is the result of improved vibrators and nozzles. Program to ensure the stability of processing currently in order to improve the operating speed of the machine, the laser machine commonly used flight structure commonly known as the light, that is, the material tray does not move the processing head in the entire machining area in the form of movement. In order to compensate for the change of the relative position of the processing head and the light source, various manufacturers also try to ensure the consistency of the light spot within the processing range as much as possible. The use of the variable curvature refracting mirror is a universal choice.

The mechanical structure incorporates an imported manipulator, a six-axis linkage and a green laser pointer beam guide fully integrated in the robot arm, combining the advantages of a stable laser with a moving robot arm. Which can realize the processing of arbitrary curve and specific curve in three-dimensional space, convenient operation and control, high degree of intelligence, greatly reduced cycle time, and guaranteed high running speed, high precision and high reliability of the device.

Three-dimensional laser cutting with professional motion control software to ensure cutting quality, to ensure stable operation of the device to make cutting easier and easier to operate; precision high-quality laser cutting head and servo system responsive, cutting precision, and manipulator effectively cooperate to avoid the cutting head Collision with the processing of plates, and to ensure that the focus of cutting position, to ensure the quality of cutting stability.

Industrial robots + fiber burning laser + man-machine console combination of processing, the processing technology completed at one time, incision neat without the need for reprocessing process, greatly reducing the process, reducing labor costs and mold costs of inputs, but also improve the product Grade and value added. Industrial robots greatly reduce the cost of the system cost, reduce power system costs and system operation and maintenance costs, reducing the system's footprint.

Metal foil cutting is based on the design of the battery, a roll of metal foil along the long side cut into thin strips. Applicable to this part is the infrared pulse laser, high-speed high-quality cutting electrode plating. If the cutting width and quality have more precise requirements, you can also consider the pulse green and ultraviolet light. Metal foil cutting links refer to the design of the battery, the elongated strip of the anode film and cathode film cut into the desired shape. Depending on the battery design and whether the foil is fully coated, you can select or adjust the beam to cut the coating or cut only the foil. The green laser pointer used in this section is the same as the aluminum foil slit.

The best way to cut the round hole is to 1: 1, that is, the ratio of aperture and plate thickness is 1: 1. Of course, this ratio, that is, the larger the pore size, cut out the high quality circle Hole is easier. Otherwise, when the fiber laser cutting machine energy is insufficient, the cutting hole easy to break point off point and round hole is not round the phenomenon. Round hole sometimes elliptical or irregular phenomenon This is related to the X \ Y axis motion does not match, and lead to X \ Y axis movement does not match the direct cause is the servo motor parameter adjustment is not appropriate. So the quality of cutting round hole, the servo motor also has certain requirements.

Conventional fiber lasers use fiber-coupled technology to couple multiple beam outputs together, resulting in lower brightness of the output laser. The new generation of fiber lasers uses an innovative architecture that combines the pump diodes and drivers into separate pump modules. The gain fiber is mounted in a configurable gain module that can output more than 8kW of laser power. The gain module is based on the novel main oscillator / power amplifier (MOPA) design, enabling high-brightness most powerful laser output. In addition, the Ennie laser also uses a reliable integrated backlash isolator to protect all modules from the impact of backlit light, can be high anti-material full power, uninterrupted, stable processing. These two technological innovations play a vital role in RLS applications.

As we all know, graphene can be used to manufacture a variety of electronic, optoelectronic devices, more scientists predicted that graphene will "completely change the 21st century", it is possible to set off a sweeping global disruptive new technology and new industrial revolution. It is understood that this time through laser writing to upgrade the existing graphene technology, the process is similar to the use of laser beam "hammer" metal forged into three-dimensional form. Finally, through the experiment and computer simulation, we can observe the authenticity and mechanism of the two-dimensional structure of graphene carbon atoms to three-dimensional shape.

In 2016, China's industrial laser materials processing equipment market was about $ 3.8 billion, with an average annual compound growth rate (CAGR) of 12.51% over the past five years. The growth rate in 2017 is expected to be about 22%, the value will reach 4.6 billion US dollars. From this point of view, the global market for materials processing in 2016, the total market volume of about 12.6 billion US dollars, while the Chinese market reached the global laser materials processing equipment system revenue of one-third. Global burning laser materials processing system popular markets include smart phone manufacturing, aluminum deep processing of metal sheet cutting, electric vehicle batteries and display and so on.

Like people and dogs, cats benefit from keeping fit and active. Exercise is essential for your cat’s mental and physical health. It relieves stress and boredom, improves circulation, builds muscle tone and can prevent or reduce behavioral problems. To keep your cat fit and healthy you must play with them. There’s no better way to coax those “inner panther” instincts out than with a few good interactive cat laser pointer toys.

Wand toysWand toys are a simple stick with a piece of fabric or ribbon tied to the end of it. You can wave, twitch, flutter and circle the wand around randomly so that the ribbon moves like an insect or bird or other prey. It comes with the added benefit of keeping some distance between you and your cat’s claws.

There are endless variations of this toy. Some have real feathers attached to the end. Some have sequins or fake mice filled with catnip. You’re likely to find one with the right textures to get your kitty up and moving.

Don’t leave these toys out for kitty to play with without supervision. Watch for pieces of string or other components that might fall off the toy and get swallowed by your cat. Plus, think of it as a special treat. If this toy only comes out when you play with her it will remain attractive and interesting. Afterall, how many times have you seen mice and birds hanging out around a cat?

Ball toysBall toys are also attractive to many cats. When they scoot across the floor they mimic the movement of a mouse scampering by. You can insert treats or catnip into some balls to make playing with them more rewarding and exciting for your cat. There are also ball toys with bells inside them to attract your cat’s attention.

Some ball toys you might like to try:

Mylar balls (crinkly and shiny)

Ping-pong balls (watch for wear)

Sponge balls (nice and quiet)

The majority of cats in the U.S will respond to catnip. Adding this herb to your cat’s playtime can increase her enjoyment! Try stuffing some catnip into a ball toy or spreading some out in a cardboard box. If you choose to let your cat ingest catnip, try to find one that is additive free. Beware, some cats get excited when they smell catnip. You may not know how your cat will respond. When cats get overexcited, they can sometimes bite.

Laser pointerLaser pointers are great for cats that tend to be a little lazy. Most cats will become transfixed on the ever elusive red dot. If your cat won’t respond to other toys, but will respond to a laser pointer, great! But try not to rely on a laser pointer.

Because cats can’t catch the red dot they’re likely to become frustrated. Try starting kitty out with the cat laser pointer then switching to a different toy once she get’s excited and playful. That way she’ll have something to catch.

Our cats and dogs are like any other cats and dogs. They need playtime to stay active and fit. You can help by donating cat and dog toys to the shelter. We also need people to come play with our cats and walk our dogs.

The main task of searching for extraterrestrial civilization (SETI) is to search for radio signals from other parts of the Milky Way, but now the agency is starting to embark on another approach, a method that utilizes a laser. To do this, they raise funds at Indiegogo, hoping to build a series of custom camera observatories dedicated to continuously scanning the entire sky, so they may be able to search for short burning laser signals from intelligent life.

In the past 60 years, people are generally using radio signals to find signs of extraterrestrial civilization, but in fact they are not the only one may be looking for alien life as a medium, like a laser, it can also be sent between stars information. It is understood that the laser can converge into a very tight beam and then tune into a single frequency and then penetrate the dust and gas in space. At the same time, any laser that eventually arrives on the earth can be very short, because they are not sent to the earth, but only happen to be sent to Earth in a short time. Radio is also the case, but the difference is that people on the violet laser pointer in space scanning area than the radio.

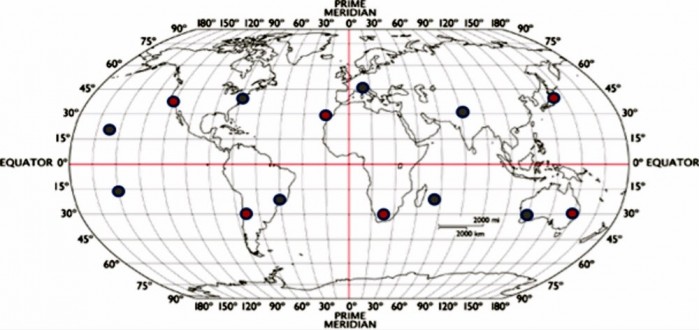

The SETI's "Laser SETI" program is designed to build such observatories around the world for the purpose of continually observing the entire sky. It will search for laptops as short as 1 millisecond or even shorter, even if duplications occur.

According to SETI's own disclosure, they have been experimenting with this project for two years, and now they are moving to a new stage. Obviously, the plan needs enough money to start. To this end, the agency in Indiegogo launched a fundraising event of $ 100,000. It was learned that the funds raised would be used to purchase the cost of the assembly and initial stages of the installation of two custom cameras and dedicated optical equipment, and the additional funds would be used in two complete observatories.

One day in the future, SETI plans to deploy 14 such observatories around the world, and then, regardless of the weather, they can start a continuous observation.

At present the world's industry recognized the fastest growing, more widely used the most important high-tech technology is optoelectronic technology, he will become the pillar industry of the 21st century. In the optoelectronic technology, one of its basic technology is laser technology. The development of red laser pointer technology and industry in the 21st century will support and promote high-speed, broadband, massive optical communication and network communication, and will lead to a lighting technology revolution, compact, reliable, long life, energy-saving semiconductor (LED) will dominate the market, In addition, it will launch a wide variety of optoelectronic consumer products and new information display technology products and into people's daily lives.

Laser energy measurement is one of the most basic elements in laser parameter measurement. It is very important to accurately determine the energy of the target laser to analyze and analyze the experimental data. The research of laser energy measurement is divided into four parts: the development of high sensitivity and high performance body absorption laser energy meter; the development of high precision and high stability display data acquisition instrument; the selection of green laser pointer energy measurement sampling method and the measures to improve the measurement accuracy; Data analysis and processing of laser energy measurement results. In the study of laser energy measurement, the development of laser energy meter is the key. The principle of laser energy meter is to be measured laser beam irradiation to a highly sensitive absorber into heat, and then through the circuit design to be truly measured out.

The new CF series lasers already incorporate advanced back-to-back reflection technology and a well-dispersed, retroreflective laser, stripping off the back-reflecting laser beam and providing safe consumption at the critical point of the laser by proprietary pattern stripping Scattered interference light. This sophisticated retro-reflective technology has been tested and its robustness has been proven to be more sensitive to back-reflecting laser pointer in kilowatt-class fiber amplifiers. The combination of these retroreflective protection schemes in the new CF series fiber lasers verifies its unparalleled performance in cutting and welding a wide variety of highly reflective metal materials with a thickness ranging from <0.5mm to thickness to 25mm.

The traditional chemical process, usually the reactants are mixed together, and then often need to heat (or also pressure). The disadvantage of heating is that the molecules produce irregular movements due to increased energy, which destroys the original chemical bonds and combines them into new bonds, and these irregularities destroy or create bonds that can impede the progress of the desired chemical reaction. However, if the laser to direct the chemical reaction, not only to overcome the above-mentioned irregular movement, but also to obtain greater benefits. This is because the laser carrying a highly concentrated and uniform energy, can be accurately hit the molecular key, such as the use of different wavelengths of ultraviolet laser, playing hydrogen sulfide and other molecules, change the phase difference between the two violet laser pointer beam, then control The molecular fracture process.

In contrast to the usual performance of third parties, and depending on the material and settings, the fiber laser has a retroreflective capability of up to 3 to 30 times the resistance due to its special optical configuration. In particular, the CF laser system incorporates these protection schemes that have demonstrated the offset error of the focal position in the millimeter scale that allows large amounts of brass and brass to be tested. Compared to other fiber laser manufacturers, it shows a smaller focus position offset error; when operating a CF laser with a unique proprietary protection scheme, the reliability of the laser and the performance of almost no failure have been demonstrated.

The application of blue laser pointer chemistry, not only to accelerate the synthesis of drugs, but also can not need to tick the side of the product, making some drugs become more secure and reliable, the price can be reduced. Another example, the use of laser control of the semiconductor, you can improve the new optical switch, thereby improving the computer and communication systems. Although the laser chemistry is still in its infancy, its prospects are bright.

http://joyreactor.com/post/3161763

http://laserman.blogghy.com/note/1491279/laser-energy-measurement-sampling-method.html

Food machinery is one of the products in direct contact with food production process, its quality directly affects food safety. Recently, the Quality Supervision Bureau found that four groups of food processing machinery failed, the overall sampling failed rate of nearly two percent. Prior to this, Quality and Technical Supervision also carried out commercial food processing equipment product supervision and spot checks, spot checks of 31 batches of commercial food processing equipment products, failed 10 batches, the failure rate of 32.3%.

By these non-qualified machinery production of goods, how many have been consumers to buy, consumption has been unable to estimate the quality of food machinery directly affect the food safety, more about people's health. All along, China's food machinery industry is facing a small and scattered, large and not the embarrassing situation, the core technology of products is difficult to compete with the developed countries. To be invincible in the international market, food production must be mechanized, automated, specialized and large-scale, from the traditional manual labor and workshop-style operation freed, improve health, safety and production efficiency.

Compared with the traditional processing technology, fiber high power laser pointer cutting machine in the food machinery production advantages. The traditional processing methods need to open mold, stamping, cutting plate, bending and other links, low efficiency, mold consumption, the use of high cost, seriously hindered the pace of food machinery industry innovation and development.

Laser processing in the application of food machinery has the following advantages: safety and health, laser cutting is a non-contact processing, which is very clean, suitable for food machinery production; cutting slit, laser cutting of the slot is generally 0.10 ~ 0.20mm; cutting surface smooth, laser cutting surface without burrs, cutting all kinds of thickness of the plate, and the truncated surface is very smooth, no secondary processing to create high-grade food machinery; speed, and effectively improve food machinery production efficiency, suitable for large The processing of products: large pieces of mold manufacturing costs are high, burning laser cutting without any mold manufacturing, and can completely avoid the formation of the material when the collapse of the pile, a substantial reduction in production costs and improve the quality of food machinery.

Very suitable for the development of new products, once the product drawings, immediately after the laser processing, in the shortest possible time to get new products in kind, effectively promote the upgrading of food machinery; saving materials, 1000mw laser pointer processing using computer programming, can be different Shape of the product of the material cut, to maximize the utilization of materials, reduce the cost of food machinery production. The future, the domestic food machinery products, food machinery manufacturing technology will be a better embodiment of information technology, digital, fine, high-speed, automation, and constantly catch up with foreign advanced level.

Since the 1970s, laser cooling technology has been used by physicists to cool a variety of individual atoms, but with its cooling molecules has been difficult. When cooling with a laser, the energy level of the system needs to match the energy level of the cooled 1000mw laser pointer. The more atoms are contained in the molecule, the more complex the vibration and rotation of the atom, the more difficult the matching and the greater the cooling difficulty. This ultra-cold molecules are expected to be the basis of molecular quantum computers, in fact, the laser can not only be used to cool molecules, but also used to accurately let it back to the original state. If the physicists can control which part of the molecule vibrates, you can use this technique to store information.

The latest research is impressive because it is very necessary to cool the molecules to such a low temperature, but there is still a long distance from the molecular quantum computer, because the progress in this area is too slow. In addition, molecules that are cooled to near absolute zero may react more slowly, allowing for more detailed observation of their reactions, so the technique may become the gospel of chemists.

Based on the coherent polarization synthesis technique of fiber optic devices, the phase coherent polarization synthesis of fiber is realized by phase control and polarization control respectively. The technology is based on the full polarization maintaining fiber best burning laser pointer device, without considering the impact of spatial error, the system is stable, reliable, easy to combine with other fiber optic devices, in the phased array based spatial coherent optical communication system has great potential value.

In order to alleviate the influence of atmospheric turbulence on coherent optical communication, two kinds of technical means are used, namely "large diameter telescope + single aperture adaptive optics" and "phased array technology". Compared with the first technology, phased array technology has the advantages of small telescope size, low cost and high reliability. In the space coherent optical communication system based on the phased array, the received light beam is divided into multiple beams by the receiving array. Therefore, it is important to synthesize a plurality of sub-beams carrying a communication signal efficiently into a brightest laser pointer beam. Aiming at this problem, the research group proposed a coherent polarization synthesis technology based on fiber optic devices.

Two linearly polarized light beams can be combined into a beam of light using a fiber polarization beam splitter, and the synthesized beam is an arbitrary polarization state due to the change in the phase difference of the input beam. In order to control the synthetic beam as linearly polarized blue laser pointer light for the next level of synthesis or for the demodulation of the communication signal, the task group proposed two methods of phase control and polarization control, and carried out theoretical analysis and experimental verification. The results show that both methods can achieve efficient coherent polarization synthesis, synthesize multiple linearly polarized light efficiently into a polarization maintaining fiber and output linearly polarized light.

The earliest mature laser radar technology is used to detect ozone, sulfur dioxide, aerosols and other atmospheric detection of brightest laser pointer radar. In 2016, in the intersection of Temple 2 and Shenzhou 11, the use of laser radar in the two spacecraft docking process to measure the relative position, angle, etc., to ensure precision docking; and China launched Chang'e III, in the landing Used to scan the bottom of the landform, detection of obstacles, this is a terrain to detect the terrain of the lidar. In recent years, with the development of artificial intelligence, automatic driving, the rise of auxiliary driving, to promote the use of laser radar in the civilian field.

From the technical point of view, there are two main types of laser radar for civilian use:

The first is a multi-beam laser side by side rotation 360 °, each beam of laser scanning a plane. Early laser radar for the 64-line (that is, 64 laser), then has to meet the needs of automatic driving, but the cost of up to 70,000 US dollars, not accepted by the market. Later, in order to reduce costs, the company launched a 32-line, 16-line green astronomy laser radar. But the cost reduction is caused by the decline in resolution, which is easy in the vehicle driving process to detect obstacles when the blind spots, bringing security risks. The second is a solid-state lidar. This technology to the United States Quanergy Systems solid-state laser radar sensor S3, led by phased array scanning, is not commonly used mechanical scanning. It does not like the first technology will produce mechanical movement, can significantly reduce production costs. But the current technology is not mature, from the product market there is still some distance.

The biggest advantage of a lidar is that it provides distance information directly. Usually we see the photo or video is a plane, which is XY two-dimensional space, but the driver is most concerned about the distance, that is, Z coordinates, which belong to three-dimensional. The biggest selling point for automatic driving is that the accident rate of road driving can be reduced to zero. Because the automatic driving is controlled by the computer, if the system does not fail, then he will strictly abide by the traffic rules, will not appear God, drunk driving and so on. But once there is a problem, such as the previous Tesla event, it will cause a great blow to the automatic driving.

Semiconductor lasers have the greatest potential as light sources. Because the size of the semiconductor blue laser pointer can be very small, the cost is relatively low, in line with the requirements as a vehicle configuration. Now we see those who installed in the unmanned roof of the laser radar, such as Velodyne, the first is not designed for automatic driving, but the automatic driving just used some of these features, such as 360 ° scan. After real use, these should be integrated into the interior of the car, for example, integrated into the position of the lamp, the semiconductor laser happens to be able to meet this condition.

Strictly speaking, there is no laser radar on the market at the beginning of the birth is designed for automatic driving optimization design. China's many domestic laser radar manufacturers produce product shape and performance are imitating the United States Velodyne company's product design. However, Velodyne company early main audio business, after the technology upgrade, only the development of the burning laser radar technology LiDAR and fame. But some of its indicators beyond the requirements of ordinary cars, brought a high cost, and some of the necessary indicators have not been achieved. Since 2016 we are engaged in this direction of research, and with the end users and some owners to conduct extensive communication to understand their needs. We want to launch a laser radar that is optimized for automatic driving. In this way can save as much as possible to save, reduce costs, can not save the place, improve the indicators, improve safety.

Lidder's market is very large, and many colleagues are engaged in the field of research and development. In fact, the largest 3000mw green laser radar market is not the field of automatic driving, but in the service of the machine robot vision. Unmanned aerial vehicles, service robots, and some entertainment projects to capture distance from the sensor, these areas of the lidar market will be greater. At present, some domestic universities, research institutes and Baidu, Huawei and other large IT companies, production and research enterprises are in the study. Experts believe that the final product development model, or should follow the R & D, the client and the market, the three closely together, starting from the initial design, so that the product can be balanced to meet the needs of all parties to play its maximum value.

Laser cutting technology is the use of high-energy laser beam heating the workpiece, so that the temperature rises rapidly in a very short period of time to reach the boiling point of the material, the material began to vaporize, the formation of steam. These vapors are ejected at high velocities, creating a cut in the material as the vapor is ejected.

Laser cutting is the use of focused high power laser pointer beam irradiation of the workpiece, so that the material is rapidly melting melting, vaporization, ablation or burning to reach the same time with the coaxial high-speed airflow with the beam blown molten material, in order to achieve the workpiece cut open. Laser cutting is one of the thermal cutting methods. Laser cutting can be divided into laser vaporization cutting, laser melting cutting, laser oxygen cutting and laser scribing and control of four types of fracture.

The use of high-energy laser beam heating the workpiece, the temperature rose rapidly in a very short period of time to reach the boiling point of the material, the material began to vaporize, the formation of steam. These vapors are ejected at high velocities, creating a cut in the material as the vapor is ejected. The vaporization heat of the material is generally large, so a large amount of power and power density is required for laser vaporization cutting. Laser vaporization cutting for thin metal materials and non-metallic materials (such as paper, cloth, wood, plastic and rubber, etc.) cutting.

In the laser melting, the metal material is melted by burning laser pointer heating, and the non-oxidizing gas (Ar, He, N, etc.) is injected through the nozzle coaxial with the light beam. The liquid metal is discharged by the strong pressure of the gas to form the incision. Laser melting does not require the metal to fully vaporize, the energy required is only vapor cutting 1 / Laser melting cutting is mainly used for some difficult to oxidize the material or active metal cutting, such as stainless steel, titanium, aluminum and its alloys.

Laser oxygen cutting principle is similar to oxygen acetylene cutting. It uses laser as a preheating heat source, with oxygen and other reactive gases as cutting gas. On the other hand, the molten oxide and the molten material are blown out from the reaction zone to form a notch in the metal. In this way, the gas is oxidized and the oxidation heat is released. As the oxidation process in the cutting process produces a lot of heat, so the laser oxygen cutting the energy required is only melt cutting 1/2, and cutting speed is much larger than the laser vaporization cutting and melting cutting. Laser oxygen cutting is mainly used for carbon steel, titanium steel and heat-treated steel and other easily oxidized metal materials.

Laser scribing is the use of high-energy-density 1000mw laser pointer scanning of the surface of brittle materials, the material heated to evaporate a small tank, and then apply a certain pressure, brittle material will crack along the small slot. Lasers for laser scribing are typically Q-switched lasers and CO2 lasers. The controlled fracture is a steep temperature distribution created by the use of a laser scribe, creating localized thermal stresses in the brittle material and breaking the material along the trough.

The laser beam is focused into a very small spot of light, resulting in a very high power density at the focal point. At this time the beam of heat input is far more than the material reflection, conduction or diffusion of the material quickly heated to the degree of evaporation, the formation of holes in the evaporation. As the beam and the material relative to the linear movement, so that the formation of continuous narrow width of the kerf. Cutting edge heat affected is very small, basically no workpiece deformation.

During the cutting process, additional auxiliary vapor which is suitable for the material to be cut is also added. Oxygen is used as an auxiliary gas in the cutting of steel to produce an exothermic chemical reaction with the molten metal to oxidize the material while helping to blow away the slag in the slit. Cutting a class of polypropylene using compressed air, cotton, paper and other flammable materials using inert gas cutting. The auxiliary vapor entering the nozzle also cools the focusing lens to prevent dust from entering the lens holder and contaminating the lens and causing the lens to overheat.

Color of the laser The color of the laser depends on the wavelength of the laser, and the wavelength depends on the active material that emits the laser, that is, the material that produces the laser after being stimulated. The ruby can be stimulated to produce a deep rosy 5000mw laser pointer beam, which is used in the medical field, such as for the treatment of skin diseases and surgery. Argon gas, which is recognized as one of the most expensive gases, produces a blue-green laser beam, which has many uses, such as laser printing, and is indispensable in microsurgery. The laser produced by the semiconductor emits infrared light, so our eyes can not see, but its energy just to "read" the CD, and can be used for optical fiber communication. Laser separation technology Laser separation technology mainly refers to the laser cutting technology and laser drilling technology. Laser separation technology is to focus energy into a small space, access to 105 ~ 1015W / cm2 very high irradiation power density, the use of this high-density energy for non-contact, high-speed, high-precision machining methods. With such high optical power density, laser cutting and punching of virtually any material is possible. Laser cutting technology is a new kind of cutting method that can get rid of the traditional mechanical cutting and heat treatment cutting. It has higher cutting precision, lower roughness, more flexible cutting method and higher production efficiency. The laser drilling method, which is one of the methods for machining holes in solid materials, has become a processing technology with a particular application, mainly in the aerospace, aerospace and microelectronics industries.

The color of light is determined by the wavelength (or frequency) of light. A certain wavelength corresponds to a certain color. The wavelength range of sunlight is about 0.76 microns to 0.4 microns, corresponding to the color from red to purple a total of 7 colors, so the sun does not mention monochrome. Single-color light source known as the single-color light source, which emits a single wavelength of light. Such as krypton lamp, helium lamp, neon lamp, hydrogen lamp are monochromatic light source, only the emission of a certain color of light. Monochromatic light source although the wavelength of a single, but there is still a certain range of distribution. Such as the neon emission red light, monochromatic good, known as the highest single color, wavelength range is still 0.00001 nm, so neon red light, if carefully identified still contain dozens of red . It can be seen that the narrower the wavelength distribution of the optical radiation, the better the monochromaticity. The brightest laser pointer output light, the wavelength distribution range is very narrow, so the color is very pure. The output of red He-Ne laser, for example, the wavelength distribution of light can be narrowed to 2 × 10 ^ -9 nm, is the krypton lamp emitted red light wavelength distribution of two ten thousandths. Thus, monochromatic lasers far more than any one kind of monochromatic light source.

Laser has many characteristics: First, the laser is monochromatic, or is a single frequency. Some lasers can produce lasers of different frequencies at the same time, but these lasers are isolated from each other and are used separately. Second, the laser is coherent light. Coherent light is characterized by all of its light waves are synchronized, the whole beam is like a "wave train." Again, the laser is highly concentrated, that is to say it will take a long distance to the phenomenon of dispersion or convergence. Laser (LASER) is the last century 60's invention of a light source. LASER is the acronym for "amplified stimulated emission" in English. There are many kinds of lasers, ranging in size from a few soccer fields to a grain of rice or salt. The gas lasers include helium-neon lasers and argon lasers; solid-state lasers have ruby lasers; semiconductor lasers have 2000mw laser pointer diodes such as those found in CD players, DVD players, and CD-ROMs. Each of these lasers has its own unique method of generating lasers.

Fiber laser is regarded as the third generation of the most advanced industrial processing lasers, but also the world's efforts to develop high-end red laser pointer. As an emerging laser technology, more and more accepted by people, fully demonstrated the competitiveness of fiber lasers. The next period of time will become the field of fiber laser lasers in the mainstream of the voice, as the major laser companies must fight to.

International fiber lasers and domestic fiber lasers in the market after the test, is now facing a clear market prospects. The good development of fiber lasers is inseparable from its unique advantages, because the laser medium of fiber lasers is itself a guided wave medium, the coupling efficiency is high; fiber lasers can be easily connected with the current optical fiber transmission system efficiently; Fiber laser has a high conversion efficiency and a very low threshold; fiber strongest laser pointer output wavelength covers a wide range, from 400 to 3400nm, to meet the needs of all aspects of the application of fiber laser can achieve high power density; fiber optic heat dissipation performance , In the industrial and commercial, communications, military, medical and other areas have a good application prospects, so the fiber laser market is also a huge potential space.

International fiber laser main manufacturers are IPG, SPI, GSI, JDSU, TRUMPF and other companies. Among them, represented by IPG, its fiber lasers occupy a larger market share in the international market, maintaining a strong growth momentum, TRUMPF also received substantial growth.

Domestic fiber laser research began in the late 90s of last century, Nankai University in China took the lead in the development of fiber laser research, followed by the Shanghai Institute of Optics and Gynecology, China Soldier clothing, 11, Many studies have been carried out, but these studies have yet to be further improved. In the context of high technical barriers to fiber burning lasers for sale, the development of domestic fiber lasers are also facing many problems. With the transformation of many laser companies into the fiber laser market, increase investment in research and development of fiber lasers, the future competition will become increasingly fierce. To gain market advantage in the future, grasp the future trend of fiber laser market trends and technological development is very important. In general, fiber laser market trends and technological development trends are the following two points:

First, fiber lasers themselves improve performance. How to improve the output power and conversion efficiency, optimize the beam quality, shorten the gain fiber length, improve system stability and make it more compact and compact is the future focus of the field of fiber lasers. Second, the development of new fiber lasers. In the time domain, ultrashort-pulse mode-locked fiber lasers with smaller duty cycle have been the hotspot in green laser pointer field research. High power femtosecond pulse fiber lasers have been the long-term goal. In the frequency domain, broadband output and tunable fiber lasers will become a hotspot.

In the next few years there will be greater development of fiber lasers, all manufacturers are also facing greater competition, but also to face the competition of imported parts, so it is both opportunities and challenges.

The localization and industrialization of fiber lasers will greatly enhance the development of China's high-end lasers, while China's high-power laser processing equipment to provide the core technology, greatly promote China's laser processing industry. At this stage, we have made some achievements, but in the fiber laser industry with the leading foreign level there is still a great distance. We should integrate resources, led by the government to improve the fiber 30mw laser pointerindustry chain, in order to strengthen China's fiber laser industry to contribute!