Eyes123456's blog

The mold repair and maintenance of A-MAX steel die with crack and wear were carried out by laser welding, and the microstructure, tensile property and fatigue property of the die were analyzed. The results show that there are fine lath martensite and some white ferrite structures distributed along the grain boundary in the weld zone of the high power laser pointer welding joint. The HAZ of the joint is ferrite and pearlite. After laser welding of the mold tensile strength and elongation of the new A-MAX mold 93.95% and 88.92%, and the repair of the fatigue life of the mold has been significantly improved, and the new mold fatigue cycle times in the same order of magnitude.

Mold manufacturing with the rapid development of industrial technology and expanding, in the modern manufacturing industry, especially in the field of precision manufacturing to obtain a wide range of applications, can effectively improve the utilization of materials and extend the service life of the product. With the rapid development of die-casting industry, die-casting molds on the overall mechanical properties and service life of higher demands, and because of the high cost of die-casting molds, molds in the long-term use conditions due to high-speed, high pressure, alternating hot or cold The working environment of the load causes the mold surface or the internal appearance corrosion, the wear or the crack causes the mold performance to drop, may even cause the mold to fail. The manufacture of molds involves the selection of materials, complex precision machining and associated heat treatment systems, which are expensive to manufacture and long in cycle time. Therefore, in order to avoid the mold due to cracks or wear and other forms of failure affecting production, and the use of mold repair welding technology, the technology is a die surface to solve the direct and effective method. Laser welding technology as a high-power density, energy concentration, the loss of welding consumables is small, and easy to automate the efficient high-precision welding, can achieve large penetration depth, low residual stress and deformation of the welding components, so laser pointer repair mold welding technology Because of its low cost, short cycle, good repair effect and become a common mold repair welding technology to overcome the cold welding and welding in the repair of fine mold surface defects.

Test conditions: The object of the study is a cracked engine block die casting mold. The mold material is A-MAX steel. It is refined by vacuum electroslag remelting process. The hardenability is good. The service life is 3-5 times of SKD61 steel. The crack depth is 40% lower than that of SKD61 steel. The steel has excellent resistance to cracking, high temperature toughness, high temperature strength, fire resistance and high temperature strength properties for a variety of large, complex die-casting molds. During the test, acetone or absolute ethanol was used instead of industrial cleaners for surface cleaning prior to welding. Repeated cleaning was necessary to meet the welding requirements because incomplete cleaning or secondary contamination could eventually lead to a significant reduction in repair quality .

Test equipment: laser welding equipment using SLC CNC laser multi-function machine, power 5KW, wavelength 10.6μm, the minimum spot diameter of 0.12mm, welding speed of 1m / min, shielding gas for argon.

Test method: Tensile test was carried out by using HY-932 tensile testing machine. According to GB / T 228-2002 standard, the total length of tensile specimen is 200mm, segment length is 95mm, radius of arc is 20mm, test temperature is Room temperature. The fatigue properties of the joint were tested with QBG-25 high frequency fatigue tester. The fatigue specimen was made according to GB / T 2015111-1994. The stress ratio of cyclic stress was 0.1 and the frequency was 100Hz. In order to reduce the test error, two samples of each parallel test.

Test results and analysis: can be seen from Figure 1, the center of the weld between the two plates in the phase plate. Because the base material is austenite and ferrite, the middle of the weld is fine grain structure, and the fusion zone is columnar. Because burning laser pointer welding has high peak temperature, faster welding speed and cooling rate, The heat affected zone of the laser welding of the -MAX steel mold is very small, but it can be seen that the microstructure of the heat affected zone of the joint in the mold repair is white ferrite and black pearlite structure. As can be seen from Figure 1b, A-MAX steel weld microstructure is relatively small quenching organizations, but also observed a small lath martensite and some along the grain boundary distribution of white ferrite. In addition, there is a small amount of fine precipitates in the welds of the A-MAX steel, which improves the strength of the A-MAX steel molds. Because the energy density of the laser beam is concentrated during the laser welding process, and the welding speed of the 50mw laser pointer is relatively fast, the liquid metal in the joint melting zone will solidify at a faster cooling rate, which is equivalent to a once Rapid hardening process, get the strength, hardness and plasticity of good lath martensite structure.

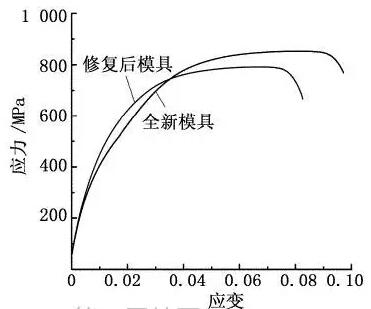

The left figure shows the results of comparison of the tensile strength and elongation of the new mold. The tensile strength of the new A-MAX mold is 843MPa and the elongation is 9.419%. The tensile strength of the A-MAX mold is 792MPa and the elongation is 8.375%. After the repair, the tensile strength of the mold reaches new A-MAX 93.95% of the mold, the elongation of the new mold also reached 88.92%. It can be seen, after 5mw laser pointer welding repair hot work die welded joints tensile strength and elongation are very close to the new A-MAX mold, with better mechanical properties. The reason for the weld strength at the mold repair site is close to the A-MAX steel base material, because the mold repair site is the highest energy and temperature zone in the laser welding, resulting in the welding zone in the welding direction is greater than the welding temperature Ac3 line temperature, and A-MAX steel quenched and tempered composition was more evenly distributed. So that at high temperature conditions, carbon and other alloying elements can be fully diffused, easy to obtain a uniform composition of austenite organizational structure. In addition, the green laser pointer welding speed is faster, and then the weld zone will melt rapidly at a rapid rate of cooling down, and finally the formation of regularly arranged carbon-lean lath martensite and a small amount of residual ferrite, and by laser welding , The lath martensite structure obtained by welding joint is more fine.

The figure on the right is the results of fatigue tests on two specimens tested on a QBG-25 high-frequency fatigue tester. Sample 1 and Sample 2 are fatigue samples of the restored mold, and Sample 3 and Sample 4 are fatigue samples of the new mold. It can be seen that the number of fatigue cycles of sample 3 is the largest, and the average of two tests is 20619 times. The average number of fatigue cycles of A-MAX mold 1 and sample 2 is 17322 times, 83.69%. It can be seen, the mold is about to scrap the use of laser repair welding after the high-frequency fatigue life is improved, close to the new A-MAX mold, and with the new mold fatigue cycle has been in the same order of magnitude.

The microstructures of HAZ are ferrite and pearlite microstructure, and the microstructures of the joint HAZ are ferrite and microstructures. The tensile strength and elongation of the hot work die were 93.95% and 89.92% of that of the new A-MAX mold, and the mechanical properties of the mold after the repair were close to that of the new A-MAX mold. After 2000mw laser pointer welding repair Thermal die fatigue life of about 83.69% of new mold, with the new mold fatigue cycle has been an order of magnitude.

http://socialenginepro.com/demo_i_love_metro/blogs/11020/17946/the-best-currently-available-hom

With the "Made in China 2025" planning and implementation, for the automation, intelligent put forward higher requirements, bear the brunt of the manufacturing sector. How to adapt to the transformation and upgrading requirements, how to enhance their competitiveness, is the primary problem faced by domestic enterprises. To this end, OFweek blue laser pointer network editor interviewed AMADA (China) Company Sheet Metal Business Sales Promotion Division Sales Planning Division, Mr. Gu Diou, to explore the transformation and upgrading of the road.

It is understood that AMADA this year is the 70th anniversary of the establishment, during which AMADA has grown into the world's leading supplier of sheet metal processing. In this regard, Gu Diou said: "AMADA from a small company to grow into an international business, mainly due to we have been focused on the sheet metal processing, and continue to develop new technologies and equipment, to provide users with more efficient solution Although we have achieved impressive results in the area of sheet metal processing, such as the invention of nitrogen-cut stainless steel and laser processing machines, we are constantly experimenting with new technologies and new equipment by continually updating evolution to remain dynamic and Competitiveness! "

This MWCS2016, AMADA to bring users the latest digital sheet metal factory "VPSS 3i" concept of processing, focusing on the overall quality from the product, taking into account the most reasonable process, the most optimized paperless processing revolution, focused display A precision machining and production processing solutions. In the precision machining, the main display of the new fiber burning laser pointer processing machine ENSIS3015AJ, a few full-automatic solution EM3510ZRB and high-precision hybrid drive bending machine HG8025. The ENSIS3015AJ is equipped with AMADA's independently developed fiber laser oscillator, combined with the unique latest beam control technology, to achieve a 2KW cutting 25mm thick plate, the energy-saving effect will be maximized at the same time, variable variants for the efficient production possible. EM3510ZRB equipped with the world's unique driving mode: dual-AC servo direct-drive motor, and since the advent of the use of CNC punch press ZR turret, the most innovative. Not only can achieve high-speed, high-efficiency processing, but also to achieve the finished product without scratching the high-quality processing. Combined with ID molds and unrestricted machining construction, it is easy to cope with variants of variable production and 72 hours of continuous machining. The HG8025 maximizes the operating performance of the bending machine with its high-rigidity body + new hybrid drive system and angular solution (no bending test required and stable bending accuracy), achieving high-speed, high-precision, Of the bending process.

In mass production processing, AMADA mainly demonstrated LCG3015AJ automatic and efficient fiber 3000mw laser pointer processing machine, AE-NT + MP2512L automatic loading and unloading number of red package and 3D automatic high-precision bending machine HM. Which LCG3015AJ whether beam quality, processing efficiency, or cost-effective are in the world's best standards. AC servo drive CNC punch press AE2510NT and automatic loading and unloading device MP2512L combination, can be a long continuous uninterrupted operation, the punching capacity to maximize, and at the same time can reduce labor costs. In addition, AMADA also demonstrated the world's most high-speed pulse band saws PCSAW720, automatic tapping machine CTS900NT, mold grinding machine TOGU3.

In recent years, the industrial concept of 4.0 in the global context of rapid warming, China has also made "2025" plan in China, focusing on the direction of the intelligent transformation and upgrading, manufacturing bear the brunt. In this regard, Gu Diou said: \ This is also the AMADA digital sheet metal factory 'VPSS 3i' processing concept of innovation, the balance has been the various channels Process, through the reverse process and the introduction of the timeline to enhance the quality of sheet metal processing and intelligence level.We also continue to enhance the level of automation of sheet metal processing equipment to make it towards high-speed, high precision, low cost and energy saving and environmental protection Direction. "

"At the same time, intelligence has brought new opportunities and new challenges." Gu Diu added: "China's sheet metal processing industry has been mass production of the times, in the industrial 4.0, IoT, and China 2025 under the wave of China's sheet metal processing industry will move in the direction of polarization for the strict quality control, strict delivery orders will be more and more enterprises.In contrast, the blind pursuit of low prices, quality control is not strictly business orders Will be less and less.In the case of weak 1000mw laser pointer market, personalized customization needs become mainstream, multi-variety of small-volume production of sheet metal processing flexibility for the new requirements.AMADA digital sheet metal factory concept, through continuous optimization and balance of the To enhance the efficiency and competitiveness of the sheet metal processing industry, to meet the industrial 4.0, IoT and 2025 in China to create new requirements!

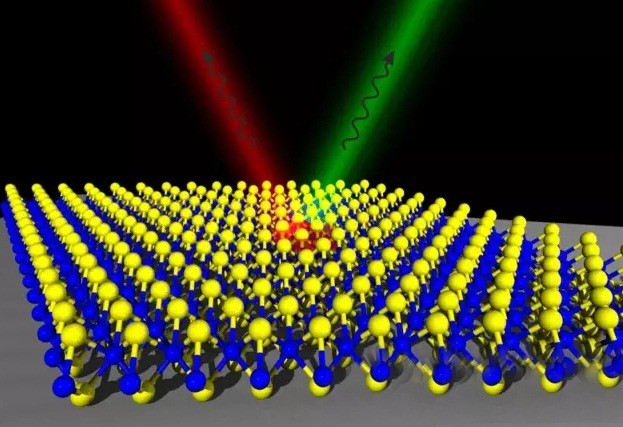

Over the past decade, the so-called single-layer materials by scientists attach great importance to these materials in the field of physics has a very large potential. At the beginning of 2016, the research team of the University of Würzburg was supported by the European Research Council (ERC) 15 million euros for the study of transition metal sulfides (TMDC). Some progress has been made.

In physics, a & quot; monolayer & quot; refers to a minimum thickness of a solid material, typically a single atomic layer thickness, and the crystalline material may be three or more blue laser pointer of atoms, also referred to as two-dimensional materials. Two-dimensional materials often exhibit unexpected properties. Such as TMDC, have similar characteristics of the semiconductor can be used to manufacture ultra-small, energy-efficient chip. TMDC has a fairly simple two-dimensional structure. Molybdenum or tungsten and other transition metal atoms in a single row structure, caught in the same thin layer of sulfur between the elements. TMDC made with different base components has a wide range of electronic and optical properties.

The team at the University of Würzburg, Germany, found that TMDC can emit light when it absorbs energy. Experiments show that this new single-layer material can be used in the manufacture of new energy efficient laser source can also be used for quantum effects research.

Quantum Communications Research: First, a single layer of material is prepared by a simple method. In the first step, the multilayer film is peeled off from the TMDC crystal with tape. A thinner film is peeled off from the multilayer film, and is repeated to obtain a single-layer material. The monolayer material is then cooled to a temperature slightly above absolute zero and excited with a 3000mw laser pointer, under which the single layer of material will emit a single photon. The researchers explained that, in fact, the excitation of two photons, light particles are produced in pairs. This photon is very interesting to the source: the photon pairs of two photon states overlap each other, entangled together. The state of one photon directly affects the other photon, and is not limited by distance, a principle that can be used to encrypt communications.

For new laser sources: Scientists at the University of Würzburg have demonstrated another application of this monolayer material. A single layer of material is placed between the two mirrors and then excited with a laser. When the laser radiation reaches a certain degree, TMDC starts to emit photons. These photons hit the mirror and send color back to the TMDC plate, which stimulates TMDC atoms to produce new photons. "We call this process a strong coupling, and the action of light and matter produces exciton-polarized photons." This is the first time that polarized photons have been detected at room temperature in monatomic layers. This "clone" photon has similar properties to 400mw laser pointer, but produces a fundamentally different principle. Ideally, after the initial excitation, new light particles can be generated by self-sufficiency, without any additional energy supply. In contrast, the laser material in the laser requires external sustained excitation.

http://laserman123.canalblog.com/archives/2016/11/08/34539740.html

http://faceluck.org/blogs/post/5908#sthash.5sempsXl.BdXjlo8t.dpbs

http://laserman123.jigsy.com/entries/general/analysis-of-the-principle-of-laser-fire-alarm-system

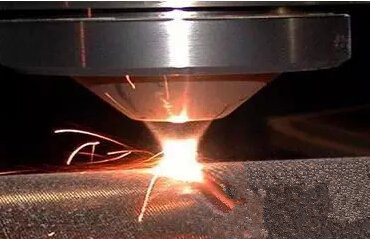

Laser cladding technology, is the 20th century, 70 years with the development of high-power laser rise of a new surface modification technology. Laser surface welding technology is the 200mw laser pointer beam, the alloy powder or ceramic powder and the substrate surface heating and melting rapidly, after the removal of the beam cooling rate of dilution formed by self-quenching, metallurgical bonding with the substrate material was the surface coating , Thereby significantly improving the substrate surface wear, corrosion resistance, heat resistance, oxidation resistance and electrical properties of a surface strengthening method. For example, 60 # steel after carbon-tungsten laser cladding, the hardness of up to 2200HV above, wear-resistant properties of matrix 60 # steel about 20 times. After laser cladding CoCrSiB alloy on the surface of Q235 steel, its abrasion resistance was compared with that of flame spraying, and the corrosion resistance of the former was obviously higher than that of the latter.

Laser cladding technology is a very cost-effective new technology, it can be inexpensive metal substrate to prepare high-performance alloy surface without affecting the nature of the matrix, reduce costs and save expensive precious metal materials, therefore, the world On the industrial advanced countries on the 10mw laser pointer cladding technology research and application of very seriously. Laser lasers used in laser cladding include CO2 lasers and solid-state lasers (including disc lasers, fiber lasers, and diode lasers), which have been phased out due to low photoelectric conversion efficiency and cumbersome maintenance.

For the continuous CO2 laser cladding, domestic and foreign scholars have done a lot of research. The development of high power solid-state lasers has been developing rapidly, mainly for non-ferrous alloy surface modification. According to the literature, laser cladding of aluminum alloy with CO2 laser, aluminum alloy substrate in the CO2 laser irradiation conditions easily deformed, or even collapse. Solid-state lasers, especially disc lasers, have an output wavelength of 1.06 μm, which is one order of magnitude lower than that of CO2 5mw laser pointer, and is therefore more suitable for laser cladding of such metals. Laser cladding, according to the different powder feeding process can be divided into two categories: Powder Preset and synchronous powder feeding method. The effect of the two methods is similar, and the synchronous powder feeding method is easy to realize the automatic control, the laser energy absorption rate is high, and no internal pores, especially the cladding metal cermets, can remarkably improve the cracking resistance of the cladding layer. Cladding uniform distribution within the advantages.

Laser cladding has the following characteristics: fast cooling rate (up to 106K / s), belonging to rapid solidification process, easy to get fine grain structure or produce equilibrium state can not get new phase, such as unsteady phase, Low dilution rate (generally less than 5%), and the matrix was a solid combination of metallurgical or interface diffusion, through the adjustment of 1mw laser pointer process parameters, you can get a good low dilution coating, and coating composition and dilution controllable; Heat input and distortion is small, especially with high power density rapid cladding, the deformation can be reduced to the parts assembly tolerances; powder selection almost without any restrictions, especially in the melting point of low melting point metal surface alloy; Layer thickness range, single-channel powder coating thickness of 0.2-2.0mm in a single time; can conduct constituency welding, material consumption less, with excellent cost-effective; beam targeting can make difficult to close the area of welding; process easy to implement Automation, it is suitable for common wearing parts wear repair.

Laser cladding and laser alloying are the rapid melting processes produced by high energy density laser beams on the surface of the substrate formed on the substrate with each other fusion, with completely different composition and properties of the alloy coating. The process is similar, but there are essentially different, the main difference: the 2000mw laser pointer cladding process cladding material is completely melted, and matrix melting layer is very thin, so the composition of the cladding minimal impact, and laser alloy Is to add alloying elements in the surface of the substrate to form a new alloy layer based on the substrate; laser cladding is not essentially the molten metal surface layer as a solvent, but will be configured separately Of the alloy powder melting, making it the subject of the cladding layer alloy, while the matrix alloy also has a thin layer of melting, with the formation of metallurgical bonding.

Laser cladding technology to prepare new materials is an important basis for the repair and remanufacture of failed parts under extreme conditions and the direct manufacture of metal parts, which is highly valued by scientists and enterprises all over the world.

https://www.pindat.com/pindata/user/laserman123.op.reis/2016-11-02