Laser Rapid Prototyping Technology from huangxiangfeng's blog

The use of laser through the interaction with the material, according to certain requirements of the processing or molding, collectively referred to as light manufacturing. Nearly 20 years, light manufacturing technology has penetrated into the high-tech fields and industries, and began to replace or transform some of the traditional processing industry. In the developed countries of the automotive industry, 50% -70% of the parts is completed by laser processing. Light manufacturing technology to improve the automotive industry R & D and manufacturing level, is playing an increasingly important role.

At present, the light source used in the light manufacturing technology is mainly laser, the high power laser pointer beam has the characteristics of high energy density, high single-palladium and high directivity, which makes the optical manufacturing technology has many advantages over the traditional manufacturing technology. The tool used in this technology is the "laser knife", no tool wear during machining; no effect of cutting force on the workpiece during machining, so the workpiece without cold processing deformation; due to high energy injection processing time, the workpiece heat is small, The laser has good spatial control (direction change, rotation, scanning, etc.) and time control (open) of the laser beam, which can not be processed by the conventional technology. , Off, pulse interval), particularly suitable for automated processing, large-scale manufacturing in the production of high efficiency; laser processing of the object material, shape, size and processing environment are great freedom; low noise, does not produce harmful rays and Residue, the production process of environmental pollution is small; can save molds, shorten product development cycle and reduce development costs; material waste, in large-scale production of low manufacturing costs.

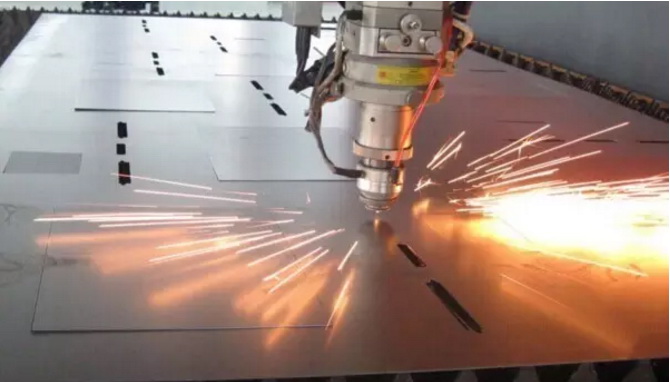

Laser manufacturing, laser drilling, laser marking and laser cutting are the key technologies for light manufacturing. No cutting stress, no cutting burr; high precision, good repeatability, do not damage the surface of the workpiece. The cutting edge is smooth, smooth cutting edge, cutting edge parallelism, no procurement follow-up processing; Laser drilling speed, high efficiency, suitable for large quantities of high-density group of holes processing; green laser pointer drilling can obtain a large aspect ratio can be hard, brittle, soft and other materials for processing, and even in the Difficult to process materials on the inclined plane processing holes; laser drilling process clean, non-polluting. Laser marking is a non-contact marking, fast, easy to wear mark, laser marking machine and very easy to combine with the assembly line. Laser cutting is similar to machining in a process of milling, it is the use of focused laser beam to cut the material layer by layer.

Laser welding is the use of high-intensity laser beam will be welded to the local melting temperature of molten metal fusion welded joints made of the process. Can weld high-melting point metal, non-metal, composite materials and other special materials, but also to achieve dissimilar materials and special welding structure welding; weld with "self-purification" effect, high quality weld; can be accurate welding, generally do not need Filling the metal; through the light guide system so that the laser beam and a number of devices constitute a flexible processing system, welding a high degree of automation, high production efficiency; high-energy beam welding, laser welding is characterized by the largest vacuum chamber does not produce x-ray .

Laser surface hardening is divided into two laser pointer hardening and laser melting hardening. Laser phase transformation hardening, also known as laser quenching, it is a high-energy laser beam rapid scanning of the workpiece, so that the surface temperature of the irradiated metal or alloy to a very fast rate to the point above the laser beam from the irradiated parts, Due to heat conduction, in the cold state of the matrix to rapidly cooling and self-quenching, get a smaller layer of hardened layer, the hardness is generally higher than the conventional quenching hardness; laser melting hardening process similar to the previous process, the difference is that the laser The surface of the material heating temperature is higher, the final part of the surface to form a layer of tissue flame hardening layer. Laser welding is the use of high-energy laser beam irradiation of the cladding material, with the substrate surface layer with rapid melting, forming with the substrate metallurgy with completely different composition and performance of the alloy coating.

Light rapid prototyping technology principle is under the control of the computer, CAD and other parts of the design model and data, the burning laser pointer beam will be forming material layer by layer curing, from the point and line structure parts of the surface (layer), the surface accurate accumulation of three-dimensional Solid model or part of the process. The use of light rapid prototyping technology, can significantly shorten the product development cycle, greatly reduce development costs, can quickly produce products to adapt to market changes, maintain and enhance the competitiveness of products in the market. At the same time, the use of optical rapid prototyping technology is also to achieve concurrent engineering and agile manufacturing effective technical approach.

The Wall