User blogs

With the average annual increase in light vehicle production to 4% by 2020, the airbag market is expected to achieve a compound annual growth rate (CAGR) of 8.1% during this period. In part because of the overall shift in growth stemming from the introduction of new safety regulations in India, China and other developing countries. By 2020, emerging economies are expected to account for 58% of global vehicle production. China alone will account for more than 30% of its commercial vehicles and passenger cars production will exceed Western Europe and North America.

Recently, large-scale airbag recalls have sparked public attention to the need to incorporate stringent quality standards into the manufacture of airbags. The impact on safety of these lifesaving equipment and equipment is a sign that consumer confidence has been eroded by relentless cost pressures on 500mw laser pointersuppliers. To win back the trust of the public, OEMs are taking extraordinary steps to ensure the safety of their passengers. These new measures, aimed at improving airbag quality control, pose additional challenges to Tier 1 suppliers, who continue to focus on reducing the unit cost of airbags in the ever-changing airbag supply ecosystem.

For mature markets, increasing passive safety will enable new airbags to achieve a wider range of applications, such as in a single advanced vehicle can have up to 12 kinds of applications. For most new vehicles, the driver side, passenger side and side curtain airbags are standard, while many passenger and light trucks are equipped with eight or more airbags. In addition, the dimensions of products are constantly evolving and evolving with the introduction of larger, wider side impact airbags, as recommended by automotive safety testing organizations such as the New Car Evaluation Procedure (NCAP).

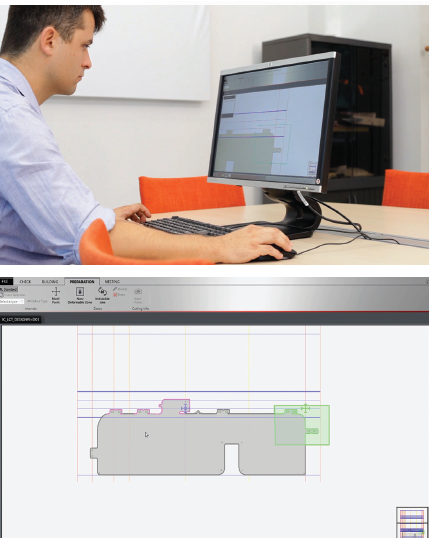

When combined with process optimization and resource optimization, the most advanced 10000mw laser pointer cutting technology can help airbag manufacturers overcome multiple business challenges. Advanced balloon design and cutting technology to meet these stringent new requirements, even in the use of low-cost materials such as polyester, but also to ensure that the final quality close to zero defect. By increasing productivity and efficiency, suppliers can achieve gains, remain competitive, and meet the increasingly demanding requirements of OEMs. Identifying anomalies during the production process can result in significant losses, such as downtime or expensive re-cutting, especially when the safety of vehicle occupants is at risk. Today, the new airbag pre-production software is designed to standardize the entire production process by validating every step of the airbag fabric preparation process.

Since the geometry of the cutting part comes from the industrial design department, in various forms, the first step is to check the unit and the consistency of the scale. The second step is to remove all the geometries that are not needed for the cut, even if the naked eye is not visible. The powerful wizard program detects and marks them to eliminate the risk of cutting 1 / 10mm holes in the center of the airbag. For multi-layer cutting, the third step involves optimizing fabric usage while ensuring laser pointer cutting quality. For a molded airbag, the next step is to build the mesh, so as to prepare for the subsequent optimization of cutting, and according to the layout of industrial loom assembly parts. Before the first cut, the necessary data is extracted in a few minutes.

The innovative use of new airbags continues to deepen both inside and outside the vehicle. Volvo and Land Rover are currently offering pedestrian airbags for selected models on the European market. In the range of 20 to 50 km per hour, these airbags are designed to minimize certain frontal impacts. Other concepts still under development include a rear airbag mounted on the front seat and roof.

Because of the aftermath of the airbag inflator scandal, the automaker has taken stringent measures to strengthen the inspection of the components of the airbag ignition system. The automated inspection system enables suppliers to ensure that their components meet stringent safety standards without slowing production schedule. For the fabric part of the airbag, the type of inflator used generally determines the choice of material. In a similar fashion, automated visual inspection has become an important part of the quality 3w green laser monitoring process. Today, automakers require many airbag suppliers to install scanners and vision systems for size control of airbag cuttings.

However, the strengthening measures only exacerbate the complexity of the manufacturing process. Despite these new development initiatives, airbag suppliers still maintain the same cost targets to make a profit. Airbag manufacturers are reaching the limit of cost optimization, so there is an urgent need to find a solution to the plight of a sharp decline in costs. This explains why many manufacturers are using less expensive materials, such as polyester fibers. However, lower costs are bound to exhibit disadvantages because the inherent resilience of these materials tends to be more severe.

Theoretically, cutting a molded airbag requires designing a starting point, and using a specific template to outline a consistent cutting path. If the material itself is completely rule-based, it will be the only operation to be performed. However, since low-cost polyesters are more elastic than other fibers, weaving and post-processing of the material may cause bending or skewing of all or part of the workpiece.

These complex problems can now be easily solved with a new generation of green astronomy laser cutting preparation software. By defining specific areas of the unmodifiable primary molding balloon design, the cutter instantaneously adapts the geometry of each cut to the actual profile of the fabric while meeting the positioning and spacing rules. The SmartCutting software demonstrates this flexible, dynamic interaction between the balloon cutting preparation software and the tool. The cut piece is sized exactly the same as the verification template and has a constant system capacity, even when cutting highly deformed materials.

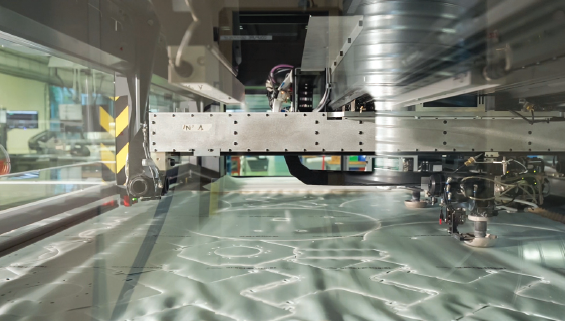

The use of a high power green laser pointer beam to cut a thick stack of cutting and suturing materials at high speed conditions and without melting the material layer requires highly precise dynamic laser power control. In fact, cutting is done by sublimation, but this can only be achieved if the laser beam power level is adjusted in real time. When the strength is insufficient, the machined parts can not be cut correctly. And when the strength is too strong, the layers of material will be squeezed together, resulting in the accumulation of fiber particles between the layers. A new generation of laser cutting machine can effectively control the laser power intensity in the nearest wattage and microsecond range.

In addition, several factors may be taken into account, such as the nature of the material to be cut, the geometry of the shape, the cutting speed and acceleration, and the like. It is also necessary to consider the workpieces cut a little earlier in order to adjust the temperature at which the risk of melting of the material in the vicinity of the zone is increased slightly and which may cause the adjacent zone to melt. This is precisely the risk of tangent, which cuts the flow through a single cutting path to ensure flawless quality.

The production process is a step that leads to profit or loss. By using the right pre-production software and the latest blue laser pointer cutting technology, airbag manufacturers can reduce their unit production costs while producing flawless products that contribute to the road safety value chain.

Mobile phone is no longer a rare thing, and now people in daily life essential personal items, instant messaging, camera, use the APP, play games and even pay for the purchase, all inseparable from smart phones. A small cell phone, even with so many features, it makes people have to wonder! And you know, green laser pointer as an advanced processing technology, in the mobile phone manufacturing process, played a pivotal role.

Laser marking is the use of high-energy laser irradiation of the workpiece on the local exposure, the surface material vaporization or color change of the chemical reaction, leaving a permanent mark of a marking method, with high precision, fast, clear mark And so on. Mobile phone laser marking this permanent marking method, can improve the anti-counterfeiting ability, but also increase the added value, the product looks higher grade, more brand. In the phone we can find the shadow of laser marking, such as: Logo marking, cell phone keys, cell phone casing, cell phone batteries, mobile phone accessories, marking, etc., even in your invisible cell phone, there are parts laser pointer .

Laser cutting can be metal or non-metallic parts and other small parts for precision cutting or micro-hole processing, cutting with high accuracy, speed, heat and other advantages. Mobile phone common laser cutting technology: sapphire glass mobile phone screen laser cutting, lens protection lens laser cutting, mobile phone Home key laser cutting, FPC flexible circuit board laser cutting, mobile phone handset network laser drilling and so on.

Laser welding is the use of high-energy laser beam as a heat source, the material surface melting and then solidified into a whole. Heat affected zone size, weld aesthetics, welding efficiency, is an important indicator of good or bad welding process. HG laser precision burning laser pointer welding machine for the processing of parts, precision instruments and other small parts, high precision welding, integrated, split and other welding supporting the choice of workstations.

Today, LDS laser direct molding technology has been widely used in the manufacture of smart phones, the advantage is that the use of laser direct molding technology marked on the phone shell antenna trajectory, whether it is a straight line, curve, as long as the laser can place, Can create 3D effects, to maximize the savings of mobile space, and can adjust the antenna trajectory at any time. As a result, the phone will be able to do more thin, more refined, stability and shock resistance is also stronger.

Personal electronic equipment, represented by mobile phones, is greatly changing and facilitating people's lives. Functionalization, intelligence, and smartness are the development direction of mobile phones. With the micro-electronics industry, technological progress and the pursuit of personalized mobile phone, fine 400mw laser pointer processing technology in mobile phone manufacturing play an increasingly important role. At the same time, the laser is also promoting the development of other microelectronics manufacturing-related industries.

http://laserman123.parsiblog.com/Posts/1/Process+Analysis+of+Laser+Welding/

http://www.elosinternacional.org/blogs/view/728/process-analysis-of-laser-welding

The mold repair and maintenance of A-MAX steel die with crack and wear were carried out by laser welding, and the microstructure, tensile property and fatigue property of the die were analyzed. The results show that there are fine lath martensite and some white ferrite structures distributed along the grain boundary in the weld zone of the high power laser pointer welding joint. The HAZ of the joint is ferrite and pearlite. After laser welding of the mold tensile strength and elongation of the new A-MAX mold 93.95% and 88.92%, and the repair of the fatigue life of the mold has been significantly improved, and the new mold fatigue cycle times in the same order of magnitude.

Mold manufacturing with the rapid development of industrial technology and expanding, in the modern manufacturing industry, especially in the field of precision manufacturing to obtain a wide range of applications, can effectively improve the utilization of materials and extend the service life of the product. With the rapid development of die-casting industry, die-casting molds on the overall mechanical properties and service life of higher demands, and because of the high cost of die-casting molds, molds in the long-term use conditions due to high-speed, high pressure, alternating hot or cold The working environment of the load causes the mold surface or the internal appearance corrosion, the wear or the crack causes the mold performance to drop, may even cause the mold to fail. The manufacture of molds involves the selection of materials, complex precision machining and associated heat treatment systems, which are expensive to manufacture and long in cycle time. Therefore, in order to avoid the mold due to cracks or wear and other forms of failure affecting production, and the use of mold repair welding technology, the technology is a die surface to solve the direct and effective method. Laser welding technology as a high-power density, energy concentration, the loss of welding consumables is small, and easy to automate the efficient high-precision welding, can achieve large penetration depth, low residual stress and deformation of the welding components, so laser pointer repair mold welding technology Because of its low cost, short cycle, good repair effect and become a common mold repair welding technology to overcome the cold welding and welding in the repair of fine mold surface defects.

Test conditions: The object of the study is a cracked engine block die casting mold. The mold material is A-MAX steel. It is refined by vacuum electroslag remelting process. The hardenability is good. The service life is 3-5 times of SKD61 steel. The crack depth is 40% lower than that of SKD61 steel. The steel has excellent resistance to cracking, high temperature toughness, high temperature strength, fire resistance and high temperature strength properties for a variety of large, complex die-casting molds. During the test, acetone or absolute ethanol was used instead of industrial cleaners for surface cleaning prior to welding. Repeated cleaning was necessary to meet the welding requirements because incomplete cleaning or secondary contamination could eventually lead to a significant reduction in repair quality .

Test equipment: laser welding equipment using SLC CNC laser multi-function machine, power 5KW, wavelength 10.6μm, the minimum spot diameter of 0.12mm, welding speed of 1m / min, shielding gas for argon.

Test method: Tensile test was carried out by using HY-932 tensile testing machine. According to GB / T 228-2002 standard, the total length of tensile specimen is 200mm, segment length is 95mm, radius of arc is 20mm, test temperature is Room temperature. The fatigue properties of the joint were tested with QBG-25 high frequency fatigue tester. The fatigue specimen was made according to GB / T 2015111-1994. The stress ratio of cyclic stress was 0.1 and the frequency was 100Hz. In order to reduce the test error, two samples of each parallel test.

Test results and analysis: can be seen from Figure 1, the center of the weld between the two plates in the phase plate. Because the base material is austenite and ferrite, the middle of the weld is fine grain structure, and the fusion zone is columnar. Because burning laser pointer welding has high peak temperature, faster welding speed and cooling rate, The heat affected zone of the laser welding of the -MAX steel mold is very small, but it can be seen that the microstructure of the heat affected zone of the joint in the mold repair is white ferrite and black pearlite structure. As can be seen from Figure 1b, A-MAX steel weld microstructure is relatively small quenching organizations, but also observed a small lath martensite and some along the grain boundary distribution of white ferrite. In addition, there is a small amount of fine precipitates in the welds of the A-MAX steel, which improves the strength of the A-MAX steel molds. Because the energy density of the laser beam is concentrated during the laser welding process, and the welding speed of the 50mw laser pointer is relatively fast, the liquid metal in the joint melting zone will solidify at a faster cooling rate, which is equivalent to a once Rapid hardening process, get the strength, hardness and plasticity of good lath martensite structure.

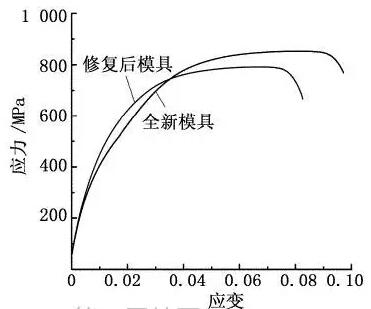

The left figure shows the results of comparison of the tensile strength and elongation of the new mold. The tensile strength of the new A-MAX mold is 843MPa and the elongation is 9.419%. The tensile strength of the A-MAX mold is 792MPa and the elongation is 8.375%. After the repair, the tensile strength of the mold reaches new A-MAX 93.95% of the mold, the elongation of the new mold also reached 88.92%. It can be seen, after 5mw laser pointer welding repair hot work die welded joints tensile strength and elongation are very close to the new A-MAX mold, with better mechanical properties. The reason for the weld strength at the mold repair site is close to the A-MAX steel base material, because the mold repair site is the highest energy and temperature zone in the laser welding, resulting in the welding zone in the welding direction is greater than the welding temperature Ac3 line temperature, and A-MAX steel quenched and tempered composition was more evenly distributed. So that at high temperature conditions, carbon and other alloying elements can be fully diffused, easy to obtain a uniform composition of austenite organizational structure. In addition, the green laser pointer welding speed is faster, and then the weld zone will melt rapidly at a rapid rate of cooling down, and finally the formation of regularly arranged carbon-lean lath martensite and a small amount of residual ferrite, and by laser welding , The lath martensite structure obtained by welding joint is more fine.

The figure on the right is the results of fatigue tests on two specimens tested on a QBG-25 high-frequency fatigue tester. Sample 1 and Sample 2 are fatigue samples of the restored mold, and Sample 3 and Sample 4 are fatigue samples of the new mold. It can be seen that the number of fatigue cycles of sample 3 is the largest, and the average of two tests is 20619 times. The average number of fatigue cycles of A-MAX mold 1 and sample 2 is 17322 times, 83.69%. It can be seen, the mold is about to scrap the use of laser repair welding after the high-frequency fatigue life is improved, close to the new A-MAX mold, and with the new mold fatigue cycle has been in the same order of magnitude.

The microstructures of HAZ are ferrite and pearlite microstructure, and the microstructures of the joint HAZ are ferrite and microstructures. The tensile strength and elongation of the hot work die were 93.95% and 89.92% of that of the new A-MAX mold, and the mechanical properties of the mold after the repair were close to that of the new A-MAX mold. After 2000mw laser pointer welding repair Thermal die fatigue life of about 83.69% of new mold, with the new mold fatigue cycle has been an order of magnitude.

http://socialenginepro.com/demo_i_love_metro/blogs/11020/17946/the-best-currently-available-hom

Fiber laser is a laser cutting machine is the core component, in general, it has played a significant effect on the cutting laser cutting machine. When choosing laser cutting machine, fiber laser customers are very focused brand, even the life of the module integrated manner. Well, today on the high-energy 30000mw laser pointer to tell you about the fiber laser modules.

Fiber laser modules are divided into single-mode and multimode, in cutting applications, a focused spot has a great influence on the cut quality, relatively small core single-mode lasers, beam quality is better than multi-mode, energy distribution Gaussian distribution, the highest energy density in the middle, three-dimensional figure is a sharp mountain-like circle.

Multimode lasers compared to thicker core, single-mode beam quality to be worse compared to the distribution of energy as compared to the average number of single-mode light spot, a three-dimensional image inverted cup from the edge steepness of view, than multimode many steep single-mode.

1mm sheet cutting speed multi-mode single-mode than 20% higher, the visual effect is almost, but 2mm start, the speed advantage of the gradual decline from the beginning of 3mm, both speed and effect, the advantages of high-power multimode green laser pointer speed and effectiveness is very obvious It reflected. So the advantages of single-mode in the sheet, multimode advantages planks, single mode and multimode not mutually comparable value, is a fiber laser configuration, like a car, cars for the road, suitable for cross-country mountain but cars also run mountain, cross country and road run, so choose multimode fiber laser in the end depends on the actual end-user or single-mode processing needs.

So single-mode and multi-mode, how do we choose?

High Energy Laser suggestions: differentiate from the power level, the lasers 1000W or less because of the energy itself is not high, mainly in favor of the sheet processing of material thickness, and therefore within the single-mode 1000mw green laser 1KW configuration is in line with the actual market situation, more than 1KW of power to take into account the laser Bohou. From the entire industry in terms of processing, improve processing quality is a rigid demand, is not compromise, so a lot of high-power single-mode laser selection will not be considered to be the quality assurance process for the first!

At the same time, the single-mode core is generally smaller, which means the same power of the laser light energy transfer in which single-mode core carry more, the material is a challenge, but when cutting highly reflective material, high intensity reflection laser light emitted overlay, if the fiber material is less than the tolerance will be very easy to "burn core", while the core material life is also a challenge! So many laser manufacturers in the high-power fiber 500mw green laserconfigurations still use multimode Configuring!

Daily life, a lot of news such as rising oil prices, energy crisis, global climate change will cause us to panic for the future. The current consensus is that we need to reduce dependence on oil in favor of clean energy, avoiding harm to our planet. This view is the people and governments around the world wide support, even in the United States. Scientists in various countries around the world are looking for alternative sources of energy, such as renewable energy sources like wind, biofuels and solar energy.

In mid-century, Bell Labs invented the "Bell of solar cells," but its high cost limited the development of solar cell industry, even after 55 years since then, solar photovoltaic power generation in the global grid accounted for only about 0.04% . However, the situation has changed in recent years, from flat panel display and semiconductor industries burning laser processing technology derived from the solar industry, there has been explosive growth.

Currently there are three common commercial application of solar cell technologies: multi-junction cells, crystalline silicon cells and thin film batteries. Multi-junction cells prepared by application on a single crystal substrate by chemical vapor deposition techniques, has the highest electron conversion efficiency (typically 28-29%, and even up to 40%). As production costs are very expensive, they are typically used regardless of the cost or effective area smaller applications, such as satellite or solar concentrator. Crystalline silicon cells most widely used efficiency monocrystalline or polycrystalline silicon is roughly 13% to 22% range. Thin film battery is a new technology, (8-18%) and low production costs are relatively low efficiency.

Crystalline silicon cells occupy approximately 93% of the PV market. In 2006, solar applications beyond the semiconductor industry, silicon has become the most important application direction (55%), which makes a significant increase in demand for silicon, silicon and caused prices to rise rapidly. So people began to look for alternatives, such as thin-film batteries. Cells are typically made of different multilayer thin film materials deposited on a glass or metal substrate, a common structure as shown in FIG. Most of absorbent material used is amorphous silicon, cadmium telluride (CdTe), copper indium gallium diselenide (CIGS). An outer electrode of the cell is typically made of indium tin oxide (ITO), zinc oxide (ZnO) conductive glass (the TCO), aluminum and molybdenum and other metals. Diode-pumped 30000mw laser pointer commonly used for connecting and insulating portions crossed at different levels.

Laser ScribingThe first step in the manufacture of thin film battery is on a glass substrate coated with electrodes, this coating is typically ITO (Indium Tin Oxide, light transmissive material). Then P1 scribing process electronic circuits, commonly used Q-switched laser wavelength of 1064 nm and 12-15 W average power. To improve the yield, the laser must be 100 KHz above the high repetition rate for rapid scanning, pulse width should be very narrow (15-40 ns) so that the peak power is higher than the ablation threshold of the material.

To achieve this ideal laser machining process include Spectra-Physics (Spectra-Physics) the Navigator, Hippo or Talon series, currently the world have installed hundreds of sets of such a laser scribing photovoltaic device. Quality spot and pulse stability is also very important to make sure that they are crossed quality, repeatability and reliability of the key. Once the ITO layer is completed, the panel returned to a chemical vapor deposition apparatus, the semiconductor film (amorphous silicon layer).

After the P2 laser process using 532 nm laser scribe from the back of the glass. Similarly, high repetition rate and short pulse width (15-30 ns) is the best, and the process power requirements are not high (typically less than 1W). So you can use a low-power green laser, or a laser beam into a plurality of 4-6 W of simultaneous multiple processing. When the P2 process is complete, the battery back-plate electrode coating (usually aluminum), and finally P3 laser scribing process, which is from the back through the glass substrate, and using the same green laser pointer process and P2. Good quality spot and pulse stability is particularly important to avoid harm to other material layers. P2 and P3 applied to the process of Spectra-Physics Lasers have the Navigator, Hippo and Talon Series green (532 nm).

The biggest advantage over conventional silicon thin film battery cell is full automatic production line, flat panel display equipment coating equipment manufacturer Applied Materials, Oerlikon, Ulvac and Leybold has recognized this opportunity, we began the development of automated production lines. It's the same as the flat panel display market principles to reduce costs by increasing the processing area.

The laser system is an important part of this online automated production lines. As used in the semiconductor and flat panel display, like a laser shine also make solar cell market.

http://www.everyonetobuy.com/best-10000mw-green-handheld-burning-laser-pointer-pen-flashlight.html

Laser technology is one of the four great inventions of the twentieth century and atomic energy, semiconductor and computer par. Thirty years to the laser-based laser technology in China has been rapid development, is now widely used in various fields of industrial production, communications, information processing, medical, military, culture, education and scientific research, and achieved good economic and social benefits to the national economy and social development will play an increasingly important role. Development of short green laser pointer, high-tech, professional, development of the industry segment is the main line, and more to a certain industry or a certain power to segment the market. As the market needs of small and medium power laser cutting industry has been dominated by the laser market dominance. Although the Chinese small and medium power laser cutting equipment industry is still in the early stages of growth, the domestic laser equipment manufacturing enterprises generally smaller scale, much more than one hundred million yuan of annual sales revenue of laser equipment manufacturing enterprises, but laser equipment manufacturing enterprises have a very large space for development.

Laser cutting technology Introduction: Laser cutting is one of the thermal cutting method using a focused high power density laser irradiation parts, so that the irradiated material rapidly melting, vaporization, ablation or achieve ignition, and by means of high-speed air stream coaxial with the beam blowing molten material, in order to achieve the cut workpiece. Small and medium-power laser processing technology is advanced manufacturing technology. Compared to the traditional processing technology, small and medium-power 30000mw laser pointer processing methods for the non-contact processing, no "tool" wear machining, processing speed, no noise, no pollution, is the green manufacturing technology; in addition, the laser processing can be personalized, diversification process, because no mold, shorten the processing cycle, saving processing costs, improve processing efficiency.

Laser means that the material produced by stimulated emission light, laser light having a good monochromatic, coherent and directional, the characteristics indicated by the frequency or wavelength (λ). Laser processing is the use of a burning laser pointer beam interaction with the material properties of the material (including metallic and non-metallic) surface treatment, cutting, welding, drilling and micro-processing of a processing technique that involves light, mechanical, electrical, materials and testing and many other subjects

.Trade advantages and characteristics of small and medium power laser cutting technology alternatives advantages: technical and economic advantages; energy-saving and environmental protection, green manufacturing advantages.Industry Chain Analysis: Impact of the upstream industry. At present, the Chinese small and medium power laser cutting equipment, laser products raw materials, lenses and other precision devices mainly rely on imports; most other raw materials and accessories are available from an adequate supply of the country. Downstream industries impact on the industry. Wide range of services in the field of the industry, upstream and downstream industries and enterprises involved in more traditional manufacturing enterprises, the downstream industry development of the industry have significant traction and driving action, and therefore development of downstream production enterprises directly affects the industry market space. Currently, a number of Chinese industrial policy introduced to promote the transformation of traditional industries and industrial restructuring, transformation and development of the downstream industry provides a good policy support, is also the industry provides a historic opportunity to expand the market.

Related policy analysis: "national long-term science and technology development planning (2006-2020)" in the fifth part of the list of China will focus on the development of the eight cutting-edge technology, 2000mw green laser technology ranked seventh. In May 2009, the State Council has issued a "equipment manufacturing industry restructuring and revitalization plan", "light industrial restructuring and revitalization planning" and the textile industry restructuring and revitalization plan, "stressed the equipment manufacturing industry, light industry and textile industry equipment independent of the support, promotion of advanced manufacturing technology, the transformation of the mode of industrial development, adjusting the industrial structure. The above planning will help to accelerate the promotion of laser equipment in light industry and textile industry. In February 2009, the State Council issued the electronic information industry restructuring and revitalization plan, "the plan proposed to vigorously promote the business and service mode innovation, active use of information technology to transform traditional industries, in a new application to promote new growth. The plan will promote the development of laser equipment industry closely combined with electronic information technology, accelerate the pace of the transformation of traditional industrial 500mw green laser equipment products.

Small and medium-power laser cutting market: Over the past decade, with a new maturity by laser processing technology, highlighting the advantages of laser processing gradually reflected in all sectors of the global laser equipment manufacturing industry to achieve rapid growth. According to statistics, from 2001 to 2008 compound annual growth rate reached 13% in 2009 due to the global economic crisis, the global laser equipment sales decline, into the recovery phase after 2010, to achieve a slight increase in sales. In recent years, China has increased efforts to implement laser processing technology industry, laser equipment enterprises gradually into production as an alternative to traditional processing methods or new technology, promote the steady development of the laser industry. 2001 laser equipment market sales of only 632 million yuan, in 2008 more than 30 billion yuan, laser equipment market has shown steady and rapid growth.

http://eyes123456.pixnet.net/blog/post/194687101

In a study published in the journal Science, the development of optics may be the central part of the next generation of computers, designed to deal with the growing demand for information sharing in society.Like a vortex Laser pointer, a new type of light based communication tool can be carried out in a rapidly moving data along a circular motion.It may also be a relief to those who have a final term in the law of Moore's law. The idea of researchers will find new ways to keep computers smaller, faster, and cheaper.

"To transmit more data, while green laser pointer using less energy, we need to rethink these machines," said Dr. Feng Liang, he is assistant professor in the Department of electrical engineering at the University at Buffalo School of engineering and applied science, and is one of the study co lead author.Other co authors Dr. Natalia M. is Litchinitser, he is also a professor of electrical engineering at the University of buffalo.Also the author and: Buffalo University doctoral candidate Pui Miao, Zhang Zhifeng; Buffalo University electrical engineering assistant researcher sun Jingbo,; Buffalo University postdoctoral researcher Wiktor Walasik Dr.; and Italian Polytechnic University of Milan, a professor at the University of buffalo to graduate students Dr. Stefano Longhi.

For decades, researchers have been able to integrate enough components onto a silicon based computer chip. Their success explained why today's smartphones than in the eighties of the 20th century the world's most powerful computers have more computing power, which cost millions of dollars as a cabinet so big. Today, it is only the dollar.But researchers are experiencing a bottleneck in which existing technologies may no longer meet the social needs of the data. Forecasts vary, but many believe that this could happen over the next five years.Researchers are addressing this matter in many ways, including optical communication, which uses 5000mw green laser light to carry information. Examples of optical communications, from the old lighthouse to the modern optical fiber cable used to watch TV and surf the internet.

The burning laser pointers is a central part of today's optical communication system. Researchers have manipulated the laser in various ways, the most common is the different signal for the path, in order to carry more information. But these techniques, especially wavelength division multiplexing and time division multiplexing, have reached their limit.University of buffalo led research team proposed by another light technique known as orbital angular momentum driven laser technology, laser is placed in the center of the helical vortex model.

Usually computer today for the needs of the work is still too large, the University at Buffalo leadership team to reduce the vortex laser to compatible with computer chips. Due to the 3000mw laser pointer beam along the spiral mode, information is encoded into different vortex twists and turns, which can carry more than 10 times the linear movement of the information than the conventional laser.Eddy laser is a component of many devices, such as advanced transmitters and receivers, and ultimately it is necessary to continue to build more powerful computers and data centers.

http://www.everyonetobuy.com/2000mw-powerful-green-laser-pointer.html

http://www.everyonetobuy.com/200mw-green-laser-pointer-with-lock-switch.html

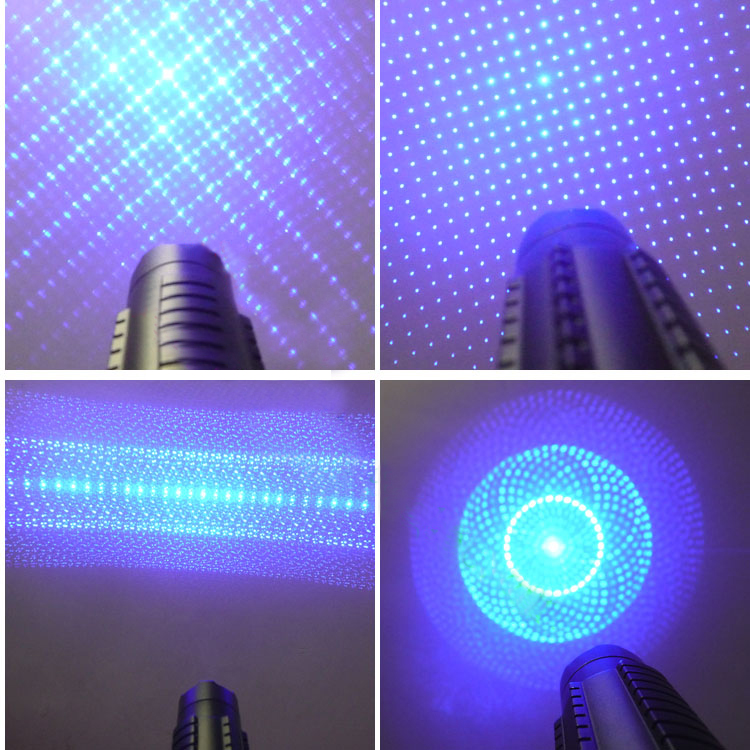

BlueTor

blue laser pointer is the most exclusive of TorLaser, being the only

blue (405nm), also achieved its incredible power: 2000mW (the actual

highest achieved in a portable laser pointer).

This power allows it to be the brightest and most spectacular of our catalog, and certainly the more power that is burning.

Its features classified him as an extremely dangerous High power green laser pointers if not used under appropriate security measures.

It provides extreme power and unique brightness.

The BlueTor addition to its incredible power, is also noted for its

exquisite design, delighting in the hands of every fan laser.

Built with the finest materials and components to provide high strength and durability.

Versatile: Incorporates 5 kaleidoscopic heads with different designs

that allow you to perform hundreds of effects, plus its switch off and

on fixed, ideal for experiments.

The BlueTor is presented in a superb aluminum case to ensure their

protection and easy transportation with all its accessories.

All these features and many more, make BlueTor one of the most powerful on the market blue laser pointers.

Green Laser Pointer are known for their small beam diameter and high power output. With the inherent human sensitivity to green color, our green laser pointers create the most powerful laser beams and brightest that can be seen anywhere. These beams carry the destructive powers so great that pass through almost any meltable and flammable object. They also travel tens and hundreds of kilometers in the dark. Exceptional power, high-energy beam intensity and super long distance, all they create a pheromone only seen in sci-fi movies. Because of these characteristics, these lasers are used by astronomers to study stars because they usually can be seen visually reaching the stars of perspective here. It is often also seen in US military operations to mislead and intimidate the enemy, because of their exceptional beam qualities and highly durable construction.

500mW Red Laser Pointer

emits invisible light, the most powerful energy beam projected useful

tasks specialized laser applications. This green laser pointer invisible

light cooperated with 2 * AAA batteries, can be a long hour of work for

5,000 hours straight. This special 500mW green laser pointer has proven

to be an ideal option for health care, military guidance and industrial

areas.

This green laser pointer projects a light visible to the naked eye

certainly will result in wonderfully controllable laser beam range of

nearly 8,000 meters. It is a 5 in 1 Laser Pointer

IR credible quality and stability, which is strictly tested before

available. You will be totally amazed by his performance monitoring,

guidance and enlightenment in the army, laboratory experiment, medical

treatment and industrial applications.Qualified laser pointer is worth

buying.

http://ec2-50-17-194-168.compute-1.amazonaws.com/account_admin/profile

https://developer.mbed.org/questions/61007/Ultra-Powerful-Laser-Pointer/