ojasvatsingh's blog

In diverse sectors encompassing agriculture, construction, mining, and manufacturing, effective management of bulk solids is of paramount importance. The continuous, unhindered flow and transfer of materials, whether they are aggregates, powders, grains, or other bulk solids, form the cornerstone of operational success. Vibration machines have emerged as indispensable instruments, significantly enhancing the efficiency of these processes while bestowing a multitude of advantages that have revolutionized the landscape of bulk solid handling.

- Enhanced Material Flow and Uniformity

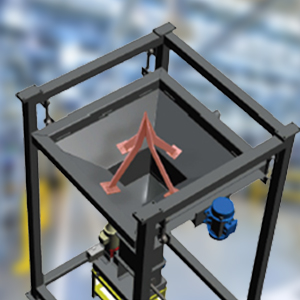

Vibration machines, often referred to as vibratory feeders or conveyors, harness mechanical vibrations to expedite the transit of bulk materials. Circular Gyratory Screens are the best. Typically, these machines comprise a trough or tube affixed to springs or hinged links, which experience excitation via an eccentric drive mechanism. This generates vibrations that enable the precise and consistent movement of materials along the trough.

The mechanism of vibration equipment operates as follows:

- Stimulation: The eccentric drive mechanism, frequently powered by an electric motor featuring an imbalanced weight, generates vibrations within the trough. Vibrating Tube Feeders Pune are used widely.

- Material Flow: These vibrations encourage the bulk solids within the trough to move in a specified direction, whether forward or upward, contingent upon the machinery's design. Many people prefer Rectangular Vibrating Screen Pune.

- Fine-tuning: Vibration machines can be adjusted to regulate the flow rate, ensuring materials traverse at the desired velocity and capacity. Bulk Bag Unloader Pune is actually fantastic.

This fundamental operational framework ensures the seamless and uniform progression of materials, effectively circumventing issues such as bridging, ratholing, or flooding. Vibrating Compaction Table Pune has been excellent. The ultimate outcome is an optimized material flow and uniformity, which stand as pivotal components of efficient bulk solid handling.

- Heightened Efficiency and Productivity

The integration of vibration machines into bulk solid handling proffers substantial time-saving benefits. You can find Circular Vibratory Screen easily. The manual creation of invoices can be a labor-intensive process, entailing the formulation of templates, data entry, and the rigorous verification of accuracy. In stark contrast, the incorporation of vibration machinery streamlines these operations by automating these tasks. Bin Activators Pune are outstanding.

These machines feature pre-defined templates, allowing for the automated calculation of totals, and also provide the flexibility to accurately include taxes and discounts. You can find Vibrating Table Pune online. This automation substantially curtails the time invested in generating professional invoices. The time economized can then be redeployed toward more productive core business activities, ultimately culminating in heightened productivity and a commensurate elevation of profitability.

- Customization and Branding Opportunities

Online tools for generating invoices offer a high degree of customization. Users are afforded the liberty to personalize their invoices to align with their brand identity by incorporating company logos, individualized details, and selecting layouts that mirror the essence of their business. People generally choose Electromagnetic Vibratory Feeder. This not only amplifies the professionalism of the invoices but also reinforces consistency in brand representation. Clients are more inclined to place their trust in and recollect businesses that present refined, branded invoices.

The utilization of vibration machines in the processes of bulk solid handling has evolved into an indispensable practice for industries reliant upon the seamless conveyance of bulk materials. People even prefer Vibratory Powder Feeder. Their capacity to ensure a consistent material flow, mitigate the risk of errors, and advance operational efficiency underscores their significance.

In numerous sectors, such as agriculture, construction, mining, and manufacturing, efficient management of bulk solids plays a pivotal role. These industries heavily depend on the uninterrupted flow and conveyance of various materials, ranging from aggregates, powders, to grains, and other forms of bulk solids. Vibration machinery has surfaced as invaluable tools in optimizing the efficiency of these operations.

- The Fundamentals of Vibration Apparatus

Vibration apparatus, also recognized as vibratory feeders or conveyors, constitute mechanical contrivances engineered to displace bulk materials through the utilization of vibrations. Typically, these machines consist of a trough or tube affixed to springs or hinged links, which are stimulated by an eccentric drive system. Bulk Bag Discharger is used widely. These resultant vibrations facilitate the orderly progression of materials along the trough.

- Initiation: The eccentric drive mechanism, typically encompassing an electric motor featuring an unbalanced weight, initiates vibrations within the trough. Bin Activator Pune has outstanding results.

- Material Propulsion: The vibrations induce the bulk solids within the trough to advance in a particular direction, contingent on the machinery's design. Bulk Bag Unloaders are the best.

- Customization: Vibration machinery can be adapted to regulate the flow rate, ensuring materials move at the desired speed and capacity. You can find Screw Bins easily.

- The Merits of Vibration Machinery in Bulk Solid Handling

The utilization of vibration machinery extends several advantages to the handling of bulk solids:

- Uniform Conveyance: Vibration machinery guarantees a consistent and uniform flow of materials, mitigating issues like bridging, ratholing, or flooding. Vibrating Feeders are affordable.

- Enhanced Productivity: By sustaining a steady material flow, these machines augment operational efficiency, thus diminishing downtime and elevating productivity levels. Vibrating Screens have the finest quality.

- Delicate Handling: Vibration conveyors are acclaimed for their gentle material handling, significantly minimizing any degradation or damage to delicate materials. Tube Vibrating Feeders are pretty fantastic.

- Personalization: Vibration machinery can be tailored to cater to specific material characteristics and process requisites, rendering them versatile across diverse industries. Compaction Tables have reasonable prices.

- Applications in Myriad Sectors

Vibration machinery finds application across a wide spectrum of industries. Let's delve into some illustrative examples:

- Agriculture: Vibration conveyors find utility in the transportation of grains, seeds, and cereals, ensuring a consistent supply for sorting, processing, and packaging.

- Mining: In the mining sector, these machines facilitate the conveyance of ores, aggregates, and minerals across different processing stages.

- Manufacturing: Vibration conveyors are engaged in the movement and feed of assorted materials in manufacturing operations, thereby elevating production efficiency.

- Food Processing: These machines gently oversee the handling of food products, such as nuts, coffee beans, and candies, preserving their structural integrity.

- The Future of Vibration Machinery

As industries continue to evolve, the role of vibration machinery in bulk solid handling is poised for expansion. Advanced control systems, heightened energy efficiency, and the proliferation of automation are poised to play a significant role in shaping the trajectory of these machines. Their contribution to sustainable and efficient material handling processes is monumental, making them an indispensable component of various industrial operations.

To conclude, vibration machinery has evolved into indispensable tools, enhancing the efficient management of bulk solids across diverse industries. Their capacity to ensure a uniform material flow, mitigate material degradation, and bolster operational efficiency underlines their significance.