MeganOwens's blog

Like to buy CAT 40 Tool holder cart,

Uratech USA Inc have six different models to chose from.

Made in USA & Same day delivery.

Powder coated - 16 Gauge steel

Angled trays are designed for convenience

Contact us :

Email …….:Info@uratechusa.com

Call us …....: 716 949 4237

Website ……: https://www.uratechusa.com/product/cnc-tool-cart/tool-carts-with-lockable-drawers-peg-board/cat-40-bt-40/

Uratech USA Inc and an ISO certified organization manufactures CAT 40 CNC Tool carts. Made in USA cart comes with Peg board and more room for tools and storage, Powder coated steel. Book now and shop online!

Contact us :

Email ………….:Info@uratechusa.com

Call us ……..: 716 949 4237

Website ……: https://www.uratechusa.com/product/cnc-tool-cart/tool-carts-with-lockable-drawers-peg-board/cat-40-bt-40/

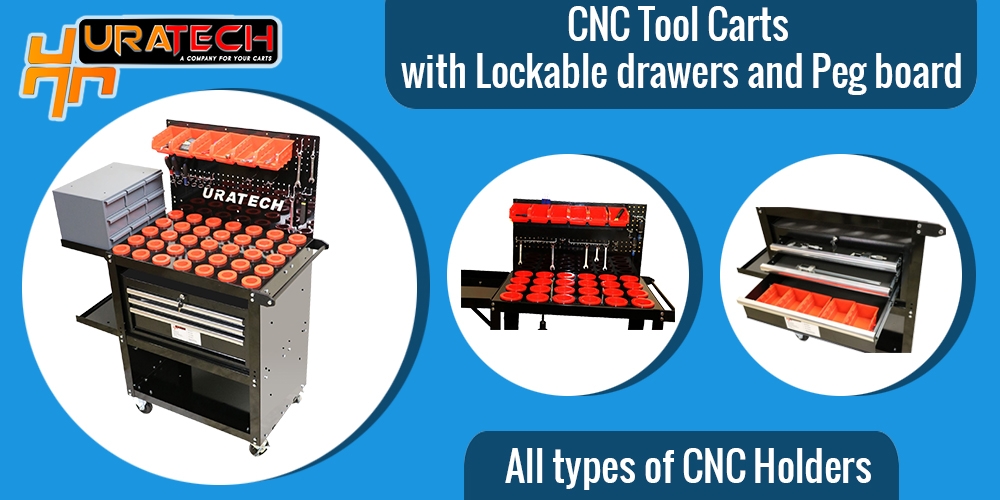

Uratech USA Inc manufactures CNC Tool Cart with lockable drawers and Pegboard for all types of CNC Holders. Made in USA, 16 Gauge steel & Powder coated.Our Tool carts come with 3 drawers with deep space to store valuable tools and secure. Pegboard with holes is provided to organize your tools and achieve 5S with more productivity.

We stand behind on our products with high quality of standards and on-time delivery worldwide. If you are looking for an industry-specific CNC tool cart with drawers to get organized, look no further as Uratech USA Inc offers the best solution for your esteemed concern.

Reach us at 716 949 4237 or Email Info@Uratechusa.com for more information.

Visit our website www.uratechusa.com and subscribe to our email list to obtain promotional offers.

All Modern Industries are equipped with CNC Machines and we are in the need to protect our valuable investments in TOOLINGS and secure them to increase productivity and obtain quick returns with profits.

Uratech’s Tooling storage solutions come in handy to serve your CNC Machines with different Models.

Choosing a right Tool storage unit is essential for productivity in any Industry.

Our Tool carts are powder coated to avoid rust and equipped with smooth rolling Industrial casters with brakes. We maintain our quality even in the casters so that our users will find a special feeling to protect CNC Tool holders while moving the carts around the shop floor.

Call us today and talk to our specialist to find the right Tool storage system for your CNC Machines at 716 949 4237 or email us at Info@Uratechusa.com

Visit us at www.uratechusa.com to explore further in detail.

We all are aware of the fast-paced working environment in the heavy machinery industry. In such an environment all departments have to work precisely without error to develop a world-class quality product. But it’s not achieved due to the frequent errors committed in the production line.

To overcome such errors and to manage all steps precisely and accurately in production, Uratech USA Inc have a solution with their Tool scoots.

Implement 5S in Work Place

5s helps to eliminate waste, streamline production, and optimize efficiencies. When you adopt 5s thinking, you commit to putting safety, organization, and effectiveness ahead of production deadlines, profits, and output. ... The key benefits of 5S include Less Waste (Improved Efficiency).

With its implementation, every employee automatically transforms himself into an organized manner and has a very less chance of committing error.

Normally 5S System is practiced in industries as a method; there were no products available to fortify its use. To fulfill that demand Uratech came up with Tool Scoots that will fit the principles of 5S Model

Uratech USA Inc has developed 6 types of Tool scoots to implement 5s in your facility.

1) CNC Mill Scoot

2) CNC Lathe Scoot

3) CNC Wire Sink EDM Scoot

4) CNC Grinding Scoot

5) Manual Mill Scoot

6) Gun Drill Cart

Why Choose Uratech Tool Scoots?

Uratech USA Inc and an ISO certified organization & an International high-quality product manufacturer ideal Tool Scoots for all types of working environment in the industry. All these products are made up of Cold Rolled Steel with 16 gauge thickness with High Strength & Durability. Each product is unique and equipped with all the necessary resources required. All these products consist of three Drawers with Ball Bearing Slides for securing Cutting Tools, Measuring Instruments & other usable items. Additional to that it also consists of pegboard with Hooks for Holding Hand Tools.

The Entire Scoot is supported by four Thick L-angled CRS Bars, with four powerful Heavy Duty Industrial Castors and a handlebar for easy movement on the Industrial Flooring. Durable Red Nylon Inserts to help prevent Tool Holder Damage in a Fast-paced industrial environment. Nylon Inserts with Lockable Tabs for placing the CNC Tool holders Fixed and prevents the Holders from Shaking in case the industrial floor as rough surfaces. The whole Body is Powder Coated with Mirror shining. Bottom Tray of these Scoots can be used for keeping consumables and other Machined components. Nylon Inserted Nuts were used to assemble this product, to avoid loosening.

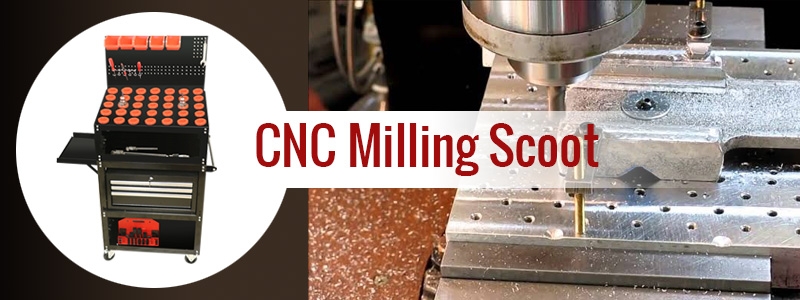

CNC Mill Scoot :

CNC Mill Scoot, Ideal for all types of Milling Machines. Made up of Cold rolled steel and has pegboard assembly comes with 6 plastic bins and Hooks, small trays at the back of the Tool cart are used to Insert boxes and small Tools.3 Drawers with ball bearings slides (Lockable). Bench Type CNC Organizer with Nylon Inserts can be used for securing cutting Tools & other small Machined Parts.

CNC Lathe Scoot :

CNC Lathe Scoot, Ideal for all types of CNC Lathes. The Top part of the Lathe Scoot consists of a Table Top or Cutting Tools and other Usable Items. Pegboard with hooks to place the most used tools. Two Collet racks installed in the cart. Heavy-duty casters for durability and easy mobility. Smooth rolling Industrial casters (1200Lbs Capacity), 2 Swivel with brake and 2 rigid.

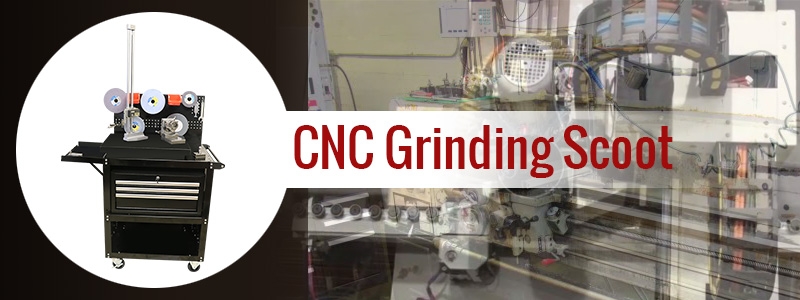

CNC Grinding Scoot:

CNC Grinding Scoot, Ideal for all types of grinding machines. The Top Part of the Grinding scoot consists of a Table Top for grinding types of equipment and other Usable Items. Pegboard with hooks to place the most used tools. Drawers with ball bearings slide (Lockable). Heavy-duty castors used for durability and easy mobility.

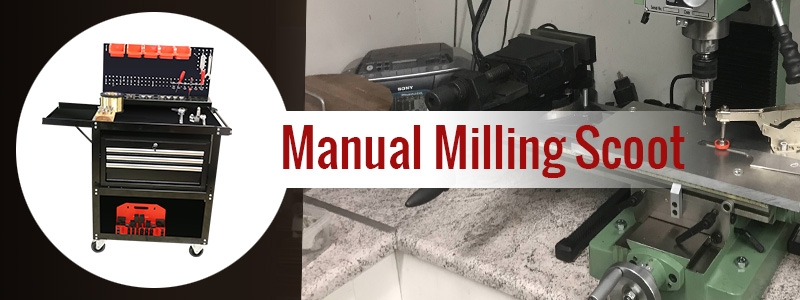

Manual Mill Scoot:

Manual Mill Scoot, Ideal for all types of Manual milling machines. The Top Part of the Manual Mill scoot consists of a Table Top for Collet Rack, Cutting Tools, and other Usable Items. Pegboard with hooks used to organize tools. Drawers with ball bearings slide (Lockable).Heavy-duty castors used for durability and easy mobility.

CNC Wire Sink EDM Scoot:

CNC Wire Sink EDM Scoot, Ideal for all types of CNC Wire Edm / Sink Edm machines. The Top Part of the EDM scoot consists of a Table Top to Collet Rack and other Usable Items. Pegboard with hooks to place the most used tools. Drawers with ball bearings slide (Lockable) Heavy-duty castors for durability and easy mobility.

Shop Tool Scoots at affordable price and best in quality from Uratech USA Inc.

Reach us at 716 949 4237 or email us at Info@Uratechusa.com to obtain more information about 5S Products Tool Scoots.

Click the link to view Tool scoots in our website,

https://www.uratechusa.com/product/tool-scoots/

Introduction

CNC Tool carts are designed especially in order to efficiently store your machine tools. Varieties of choices for a tool cart are needed for an organization according to the kinds of machines they were handling in their industrial area. Hence the market is available with different features carts for CNC, CAPTO and HSK tooling. Uratech is one such manufacturer, who majorly focus on industrial requirement and design their tool carts accordingly? One of those tools they tailored in their manufacturing unit is the CNC Tool cart with Lockable drawers and Peg board.

CNC Tool cart with Lockable drawers and Peg board.

Uratech actually manufacturers many varieties of tool carts, they have really 6 types of CNC tool carts. Every cart has its own uniqueness and advantage, mainly fast moving in the market. In this blog we are particularly going to speak about one CNC Tool Cart that comes with Lockable drawers and Peg board. Due to its uniqueness it is the most wanted product in the industry. The cart is made of Cold rolled steel with a thickness of about 16 gauge, the cart is powder coated in order to prevent the cart from easy rusting when it is exposed in the extreme industrial conditions. Durable Red nylon was used as inserts to protect Holder tapers due to its physical and chemical properties and which has high capability for thermal resistance. Cart comes with black anodized aluminum handles in order to handle the cart.2 support trays in the front and bottom of the cart is provided in order to store consumable.

Heavy duty smooth rolling industrial castors which can withhold up to 1200 lbs, the cart has 4 castors in that 2 were rigid and the other 2 has swivels (wheels with breaks), which drives the cart and controls its movement in the industrial floor .In order to cop up with the toughest industrial floor these castors were designed heavily to withstand and bear huge load and capacity, since it was one of the main reason for the carts lifetime.

How it is different from other CNC Tool Carts

Normally Uratech is very peculiar in selecting up the raw material and each product with its uniqueness and has high capability to withdraw its features and can be utilized for a longer run. It has peg boards with hooks and plastic bins for hanging tools and for placing nuts and bolts securely in plastic bin.3 drawers with ball bearing slides and lockable options to secure the valuable(Keyed internal lock system). The slides length is about 16 inches. The 3 cabinets of dimensions 26.5”*12”(wide)*12”(height, each drawers can hold 75lb.

CNC Tool cart with Lockable drawers and peg board and peg board has parts cabinet which has 9 drawers and dividers, these dividers were adjustable one and these cabinets are of dimensions 18.000” long x 12.000” wide x 11.000” ( Height ) and the cabinet drawer size is 11.250” long x 5.000” x 3.000”

Why it is the most needed

Due its longer run it is the most needed product in the market. More particularly it has that storage unit, which is capable of storing the entire essential in the work area safely. This avoids a lot of mess in the work area .Employees can store expensive tools safely and other measuring instruments like scale,tapes,calculators,vernier caliper, screws, bolts and etc. Both the machine tools and the essentials all are available in the same, and then a whole lot of effort in safeguarding these things will be very simple in a single cart. More preferably these carts were movable one; they can be easily transported from one place to another according to the convenience of work. Our carts gives a safe, comfort and easily transportable space for all the tools and essentials in one single common cart, that’s why it is the most needed one in the industry. It is highly beneficial to buy this cart as it composes of the whole lot feature and very cost effective too. The total weight of the cart is about 150lbs and the art dimension is 20”*40”*38”(height from the ground)

Conclusion

Choosing wisely according to your requirement, can save lot of your

investment. Not only investment it further increases your production level.

Never miss a cart like ours, which has many unique features and has lots of

options available in a single, actually a greatest friend for both your

employers and machines.

Call us today and talk to our specialist to find the

right Tooling storage solution for your CNC Machines at 716 949 4237 or email us at Info@Uratechusa.com

We look forward to work with your Team,

UratechUSA is a decade old concern, knowing the market standards and industrial needs. A clear understanding and the well-versed experience in the machining field guides us to create the feasible CNC storage cabinets with fine quality. Uratech always excels in their product design and quality, which helps the customer to safeguard their work place and investments. Our tool cart offers the best support to the machine tools which tends the business to increase their productivity.

A clear market study helps us to design the fine quality product which fits most of the industrial requirement. To withstand a longer run, the raw material used for manufacturing our tool carts are particularly hand-picked with extra care.CNC Tool trolley is our major product which is highly demandable one in the market. According to your industrial area and specifications, you can pick the best from our variety of tool storage trolleys we manufacture. Here in this blog, you can able to learn more about the types of CNC tool cartthat we manufacture and the raw materials used to build it.

Types of CNC Tool Cart We Manufacture:

The need of CNC tool storage cabinets will differ according to the industries. To offer the vital requirements of the customer, Uratech USA manufactures 6 types of industry specific CNC Tool carts, which suit the best for all type of industries.

· Floor Model (All types of CNC Holders)

· Steps Model (All types of CNC Holders)

· Ladder Model (All types of CNC Holders)

· Shelf Model (All types of CNC Holders)

· Secured Model (All types of CNC Holders)

· Bench Model (All types of CNC Holders)

Cold Rolled Steel:

Cold rolled steel is a type of raw material used in our unique CNC trolley manufacturing. In this process the steel metal is used to roll in the room temperature which helps the sheet to have perfect finishing and gives a good look to the CNC cart. Therefore, there will be no extra patching works needed to make it look properly. For our specific CNC tool cart, we use (16 gauge Thickness, 1.6mm (0.063”)) to gain High Strength & Durability.

Nylon Inserts:

Due to its

thermoplastic feature and its ability to withstand heat, nylons were used as

the raw material for inserts. It also gives us the great advantage of having

greater rigidity and strength. Nylon was the first commercially successful

synthetic thermoplastic polymer. These inserts were used in the industrial area

to safeguard the tools, particularly the workplace which emits greater amount

of heat.

Uratech offers 2 variants of inserts, one is lockable and the other is unlockable.

Lockable inserts firmly hold the tool in one position which prevents the Holders from Shaking while moving through rough surfaces. The lockable tool storage trolleys has its unique features which makes it the fastest moving model in the industry. UnLockable inserts can also hold the machine tools, and these types of inserts are used for specific purposes. So, according to your requirements, you can choose the best which suits your ideal needs.

Powder Coating:

Powder coating

is a procedure in which the paint is sprayed over the material to give a

perfect finish to the product. Since cold rolled steel is the raw material,

this particular method gives a unique and mirror finishing to the cart. Its unique

feature offers the CNC tool cart products to resist from corrosion and it

offers rust free industrial environment.

Nuts with Nylon:

The perfect assembly structured tool should withhold the capacity of the tool within the body strength of a tool cart. When the parts of the CNC storage cabinetsare fixed and screwed perfectly, it can bear a huge load. So, a p perfect screwing and fixing should be done to avoid accidental damages. For the finest body structure and fitness of the Cart, we use Nylon inserted nuts. Nuts with the nylon piece at the end of it help to avoid the loosening of the tool when used in the rough industrial floor. It seems the nuts and bolts were very small figure, but when compared to the lifetime of the tool, they play a major part of it.

Aluminium

handle:

Due to its lightweight, corrosion resistance, non-magnetic and many other features, aluminium is used as the raw material in most of the industrial products. At Uratech, we make use of aluminium as the raw material to make the finest tool handles which withstands for a long.

Peg Boards:

Pegboards are used in some of the CNC tool carts, as they help in hanging the tools in the stand for easy access. For slightly bigger or varied tools the hooks also differ as it needs to withstand the weight. These peg boards save a lot of time as it helps the workers to have a simple access to their tool needs whenever they require. It can also avoid lots of mess in the work area.

Castors:

Castors are the most important material for the movement of the cart on the working floor. There are 2 types of materials which were used in manufacturing our CNC tool trolley. One is rigid which allows only forward and backward movements and another one with swivels which are responsible for multiple directions. These swivels castors have the feature of breaks which allows us to control the cart quite easily. Polyurethane Caster Wheels with Ball Bearings resist most chemicals, cushion loads, and help in protecting floors. Ball bearings allow wheels to run directly on the axle or spanner bushing. Polyurethane cores help cushion loads and offer superior chemical and water resistance. These castors are made up of polyurethane to ensure smooth rolling in the industrial area. They can able to withhold a load capacity of up to 11000lbs.

Visit our website or call us anytime to know more details about the variant of CNC tool carts that Uratech USA manufactures. If there is customization to be done in the products according to your industrial needs, we deliver the best which suits your ideal requirements.

UratechUSA is a decade old concern, knowing the market standards and industrial needs. A clear understanding and the well-versed experience in the machining field guides us to create the feasible CNC storage cabinets with fine quality. Uratech always excels in their product design and quality, which helps the customer to safeguard their work place and investments. Our tool cart offers the best support to the machine tools which tends the business to increase their productivity.

A clear market study helps us to design the fine quality product which fits most of the industrial requirement. To withstand a longer run, the raw material used for manufacturing our tool carts are particularly hand-picked with extra care.CNC Tool trolley is our major product which is highly demandable one in the market. According to your industrial area and specifications, you can pick the best from our variety of tool storage trolleys we manufacture. Here in this blog, you can able to learn more about the types of CNC tool cart that we manufacture and the raw materials used to build it.

Types of CNC Tool Cart We Manufacture:

The need of CNC tool storage cabinets will differ according to the industries. To offer the vital requirements of the customer, UratechUSA manufactures 6 types of industry specific CNC Tool carts, which suit the best for all type of industries.

· Floor Model (All types of CNC Holders)

· Steps Model (All types of CNC Holders)

· Ladder Model (All types of CNC Holders)

· Shelf Model (All types of CNC Holders)

· Secured Model (All types of CNC Holders)

· Bench Model (All types of CNC Holders)

Cold Rolled Steel:

Cold rolled steel is a type of raw material used in our unique CNC trolley manufacturing. In this process the steel metal is used to roll in the room temperature which helps the sheet to have perfect finishing and gives a good look to the CNC cart. Therefore, there will be no extra patching works needed to make it look properly. For our specific CNC tool cart, we use (16 gauge Thickness, 1.6mm (0.063”)) to gain High Strength & Durability.

Nylon Inserts:

Due to its

thermoplastic feature and its ability to withstand heat, nylons were used as

the raw material for inserts. It also gives us the great advantage of having

greater rigidity and strength. Nylon was the first commercially successful

synthetic thermoplastic polymer. These inserts were used in the industrial area

to safeguard the tools, particularly the workplace which emits greater amount

of heat.

Uratech offers 2 variants of inserts, one is lockable and the other is unlockable.

Lockable inserts firmly hold the tool in one position which prevents the Holders from Shaking while moving through rough surfaces. The lockable tool storage trolleys has its unique features which makes it the fastest moving model in the industry. UnLockable inserts can also hold the machine tools, and these types of inserts are used for specific purposes. So, according to your requirements, you can choose the best which suits your ideal needs.

Powder Coating:

Powder coating

is a procedure in which the paint is sprayed over the material to give a

perfect finish to the product. Since cold rolled steel is the raw material,

this particular method gives a unique and mirror finishing to the cart. Its unique

feature offers the CNC tool cart products to resist from corrosion and it

offers rust free industrial environment.

Nuts with

Nylon:

The perfect assembly structured tool should withhold the capacity of the tool within the body strength of a tool cart. When the parts of the CNC storage cabinets are fixed and screwed perfectly, it can bear a huge load. So, a p perfect screwing and fixing should be done to avoid accidental damages. For the finest body structure and fitness of the Cart, we use Nylon inserted nuts. Nuts with the nylon piece at the end of it help to avoid the loosening of the tool when used in the rough industrial floor. It seems the nuts and bolts were very small figure, but when compared to the lifetime of the tool, they play a major part of it.

Aluminium

handle:

Due to its lightweight, corrosion resistance, non-magnetic and many other features, aluminium is used as the raw material in most of the industrial products. At Uratech, we make use of aluminium as the raw material to make the finest tool handles which withstands for a long.

Peg Boards:

Pegboards are used in some of the CNC tool carts, as they help in hanging the tools in the stand for easy access. For slightly bigger or varied tools the hooks also differ as it needs to withstand the weight. These peg boards save a lot of time as it helps the workers to have a simple access to their tool needs whenever they require. It can also avoid lots of mess in the work area.

Castors:

Castors are the most important material for the movement of the cart on the working floor. There are 2 types of materials which were used in manufacturing our CNC tool trolley. One is rigid which allows only forward and backward movements and another one with swivels which are responsible for multiple directions. These swivels castors have the feature of breaks which allows us to control the cart quite easily. Polyurethane Caster Wheels with Ball Bearings resist most chemicals, cushion loads, and help in protecting floors. Ball bearings allow wheels to run directly on the axle or spanner bushing. Polyurethane cores help cushion loads and offer superior chemical and water resistance. These castors are made up of polyurethane to ensure smooth rolling in the industrial area. They can able to withhold a load capacity of up to 11000lbs.

Visit our website or call us anytime to know more details about the variant of CNC tool carts that UratechUSA manufactures. If there is customization to be done in the products according to your industrial needs, we deliver the best which suits your ideal requirements.