The Online Advantage: Redefining Customization with CNC Machining Services from Fuson Precision Machining's blog

Is your goal to improve manufacturing process efficiency while decreasing costs? Online CNC machining services are all you require. Solving complex problems quickly and accurately is essential for businesses in today's lightning-fast business environment. An easy and practical alternative to traditional brick-and-mortar machine shops offering high-quality machining services is exactly what online CNC services offer. Whatever your size, from a large, established company to a small, fledgling startup, you may gain the competitive edge you need by taking advantage of Online CNC service. In this exciting new area of study, digital manufacturing, let's see how it might improve your production processes without draining your money account.

Critical Considerations for Online CNC Machining Services and Their Advantages

When it comes to modern production, online CNC machining services are indispensable due to all the benefits they provide. The fact that it is convenient cannot be disregarded. It is now possible to access a vast array of machining capabilities through online services, all from the comfort of your home or office. Visits to physical machine shops for project needs discussions or bids are a thing of the past.

You won't find faster or more efficient CNC services online. Rapid evaluation of your design files and accurate quotations are possible within minutes on these platforms thanks to their advanced software and automated procedures. Time is money, and this will save you both by ensuring faster project response times.

With online CNC machining, you may save money without compromising quality. On many occasions, online service providers can offer more affordable alternatives to conventional machine shops because they don't have to pay as much in overhead. Competition will increase and prices will go down even further because there are more manufacturers and suppliers to pick from.

Online CNC machining services offer multiple benefits, including convenience, speed, efficiency, and cost savings. These factors are particularly significant in today's highly competitive manufacturing industry. You may optimize production while cutting expenses by adopting digital manufacturing with online CNC services. It doesn't matter how big or small your firm is. Both large organizations looking for efficient production solutions on a large scale and small enterprises looking to prototype new goods should adopt this method.

Becoming Familiar with CNC Machining: Processes and Materials

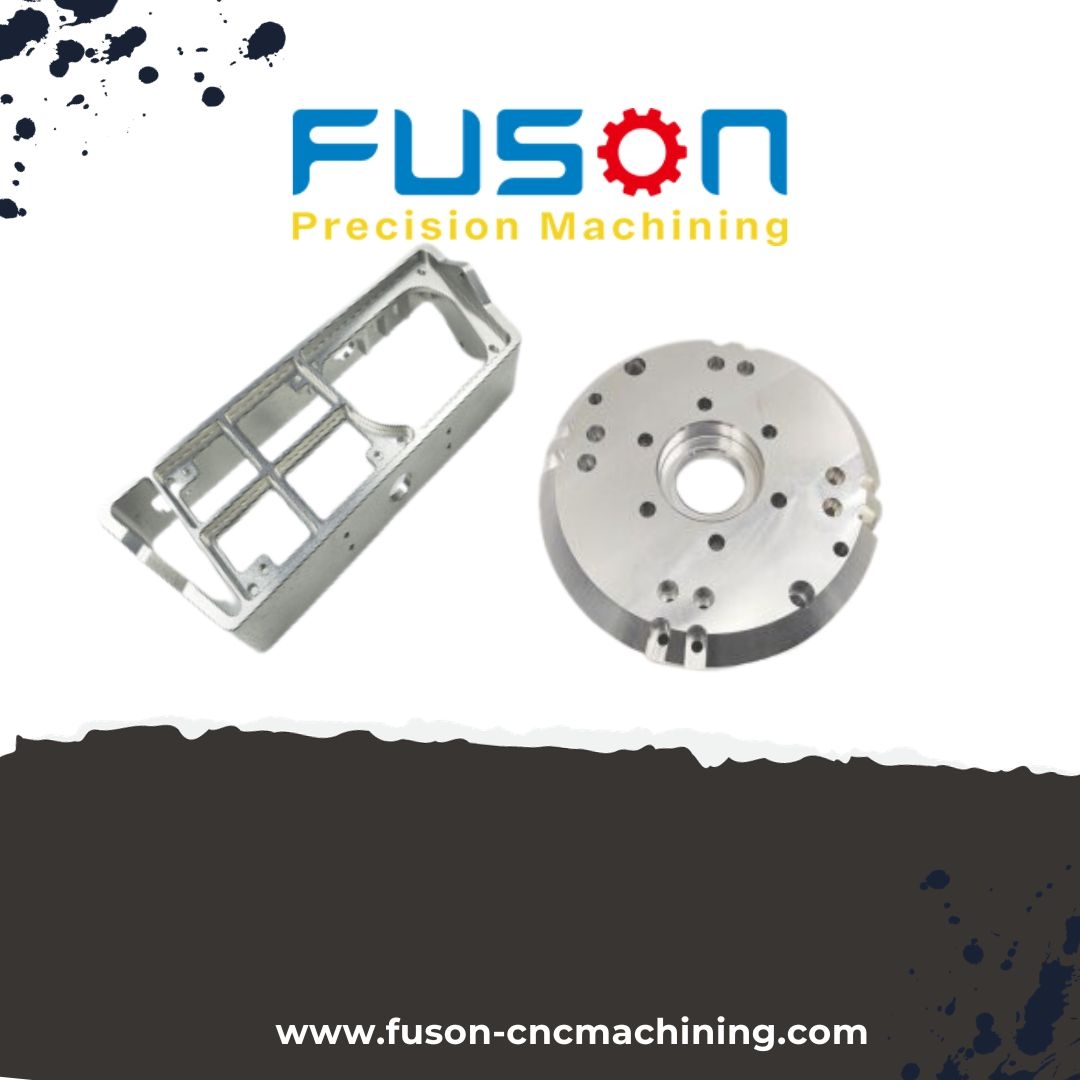

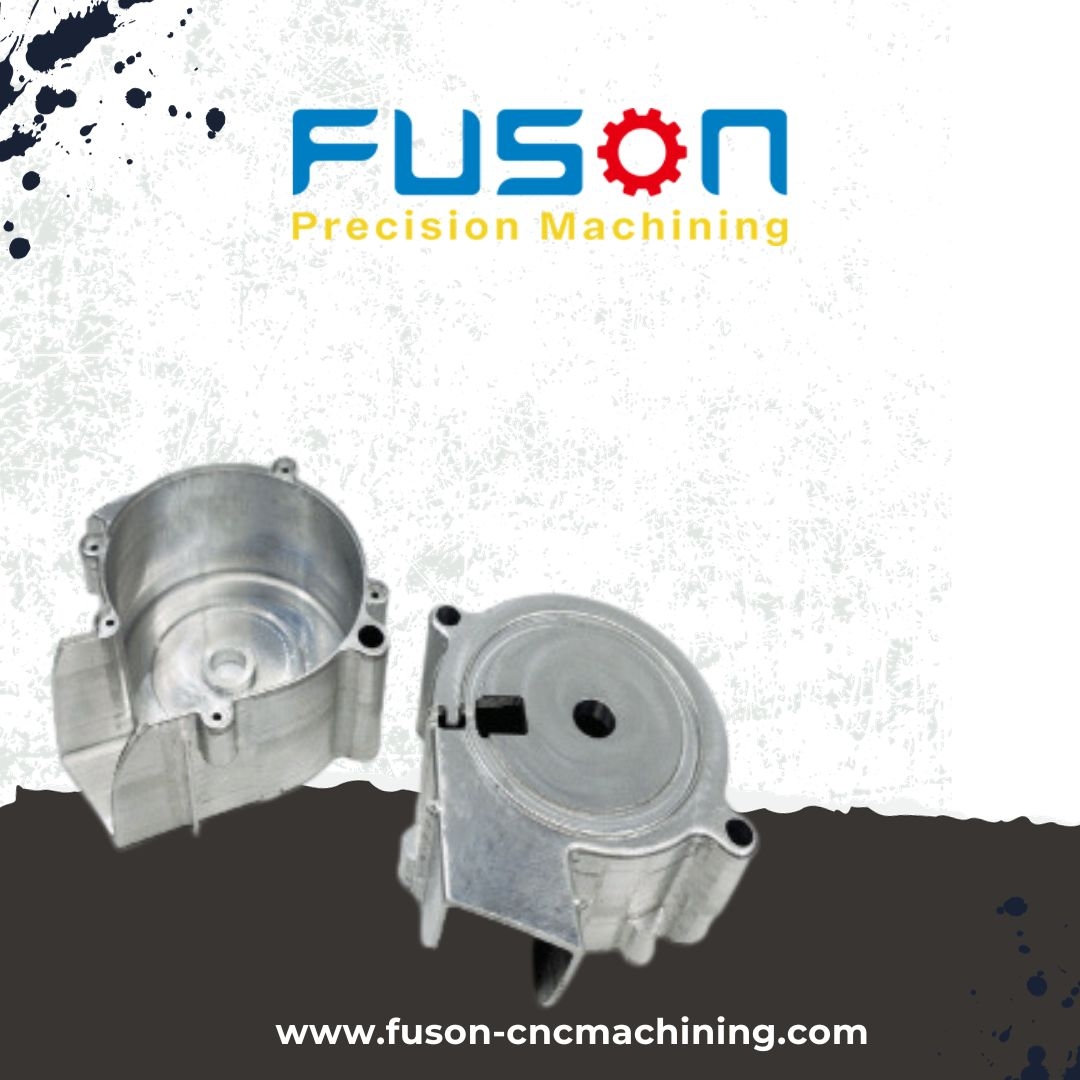

Computer numerical control machining (CNC machining) is a production process that uses automated tools and systems to provide precise and elaborate components. Technology like this has revolutionized production by making processes more efficient, precise, and adaptable.

Controlled numerical control (CNC) machining involves many critical processes. Engineers create a digital replica of the required component using specialized software in the first phase, known as design. Experts then move on to programming, the process of turning the design into machine-readable instructions. These instructions are used by the CNC machine to perform various operations, such as milling, cutting, turning, and drilling.

Each project calls for a unique set of materials, and CNC machining can accommodate those demands. Typical materials include metals such as titanium, steel, brass, and aluminum. Plastics that are both durable and pliable, such as nylon and ABS (Acrylonitrile Butadiene Styrene), find extensive use as well.

Companies can save money and work more efficiently using CNC machining services offered online by companies like Fuson Precision Machining if they are well-informed about the materials and methods involved.

Conventional CNC Machining Material Types

The key to achieving top-notch results with CNC machining is choosing the right material. Several common materials see heavy use in CNC machining processes. I propose we examine some of these in more detail.

A wide variety of sectors make heavy use of aluminum because of its exceptional strength-to-weight ratio. Due to its ease of processing, it is an excellent substitute for precisely fabricating complex components.

The strength and longevity of steel make it a popular material for CNC machining. Because of its high temperature tolerance and strong resistance to corrosion, it is a great material to use in applications that require sturdy parts.

Various polymers, such as ABS, polycarbonate, nylon, and acrylics, provide a wealth of possibilities for CNC machining. Their low price, portability, and adaptability make them ideal for a wide range of design needs.

Choosing the right material depends on a number of factors, including the desired attributes, available budget, and application needs. If you work with a CNC service provider online, you can browse their inventory and pick out the perfect material for your job.

How Online CNC Machining Services Benefit You

Efficiency and cost savings must be prioritized by every industrial organization in today's fast-paced, highly competitive business sector. The circumstance calls for the utilization of online CNC machining services. Through the utilization of the internet and technology, these services offer numerous benefits, potentially leading to a significant boost in productivity while simultaneously reducing expenses.

Avoid wasting time searching for local machine shops or waiting for quotes by taking advantage of online CNC machining services. Quickly and easily compare prices from many providers by uploading your design files. You may speed up production schedules and release products with the help of this simplified process.

Spending less on setup, materials, and labor is typical with older machining methods, which leads to cost reductions. These expenses are reduced to a large extent when using online CNC machining services because of the automated procedures used to enhance material use and minimize errors. Because of the increasing level of competition, they are able to offer reasonable prices thanks to their extensive network of manufacturers.

Using an online CNC service, you can gain access to state-of-the-art technology without breaking the bank. Reliable manufacturers with high-tech CNC technology can make complex items with pinpoint accuracy, and these platforms collaborate with them.

Online CNC machining services offer a wide variety of materials suitable for various uses, so whether you require aluminum prototypes or production components made of stainless steel or plastic, you may find what you need. You may rest assured that your specific requirements will be met by perusing their vast inventory.

Assurance of Quality: Reputable Online machine shop services employ rigorous quality control procedures all through production to make sure that each and every component meets tight industry standards.

You may trust them for precision and reliability in product quality; they have built their name on delivering high-quality items on schedule.

The Wall