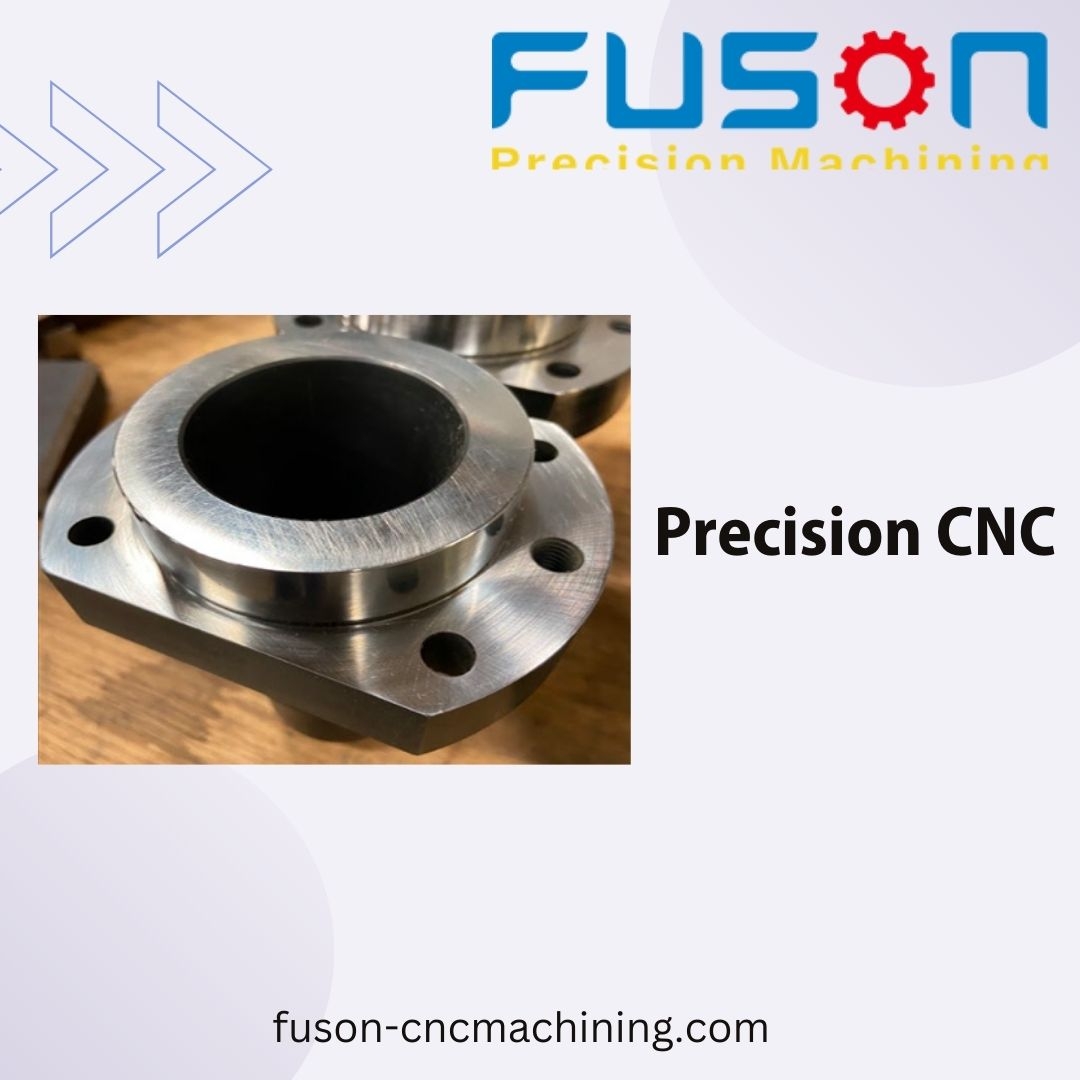

Precision CNC Machining: Engineering Perfection with Technology from Fuson Precision Machining's blog

CNC machining is state-of-the-art machinery that permits exact and reliable production. CNC machines allow you to harness the power of precision in your assembly line. CNC allows these devices to precisely implement intricate blueprints. CNC machining's consistent high quality is a benchmark in many fields. CNC machining is used in many different industries today, from aerospace to automotive. CNC machining stands out from conventional techniques because of its superior capacity to generate complex forms and patterns with finer levels of detail. These machines' accuracy guarantees uniformity and lessens room for error in manufacturing. CNC machining ensures superior quality in every item made, be it a prototype or a batch of thousands. Consequently, CNC machining should be incorporated into the production process if the company is serious about staying ahead of the competition and delivering products that satisfy the highest standards.

Accurate CNC Milling: Revolutionizing Multiple Sectors

As a result of its unrivaled precision and efficiency, CNC machining has caused a revolution in a wide variety of sectors. The use of sophisticated computer-controlled systems has revolutionized the manufacturing process, allowing for the creation of complicated and delicate components with pinpoint accuracy. Precision CNC machining has found widespread use in industries as disparate as aerospace and automotive, medicine and electronics. Today's high-performance, high-quality consumer goods are only possible because of advances in manufacturing that allow for increasingly complex designs and precise tolerances. In addition, the CNC machining process ensures that each component is identical to the last, with no deviations and few mistakes. Industries are able to achieve previously unthinkable levels of precision and inventiveness thanks to the ever-expanding capabilities of CNC machining. Precision CNC machining is still a driving force in revolutionizing industries all over the world, whether it's used to make complex components or enhance production efficiencies.

Benefits of High-Precision CNC Machines in Contemporary Production

Precision CNC (Computer Numerical Control) has completely changed the way factories operate today because of the many ways in which it improves efficiency and output. Precision CNC is capable of producing intricate parts with extreme accuracy because it employs sophisticated computer software and automated machinery. This degree of accuracy guarantees constant quality and lessens the room for error, leading to better product performance overall. As an added bonus, CNC machines can run nonstop, which boosts efficiency and productivity. Manufacturing time and money can be saved by the elimination of manual work thanks to the development of programming and automation tools. In addition, precision CNC makes it simple for factories to make exact copies of components, guaranteeing the delivery of parts that are 100% in accordance with design intent. Precision computer numerical control (CNC) has advanced to the point where it is now an essential tool in today's industry, helping to boost productivity, efficiency, and ultimately, profits.

Precision CNC Machining Services and the Variety of Materials We Work With

The diverse range of sectors served by precision CNC machining services is reflected in the wide variety of materials available for use in the process. Aluminum, steel, and titanium are just a few of the metals available; nylon and polycarbonate are two of the engineering plastics available. These components are handpicked to guarantee the highest quality and longest lifespan possible in the finished goods. Specialized applications that call for high temperature resistance or corrosion resistance can also make use of advanced alloys like Inconel and Hastelloy. CNC machining services with a focus on precision and accuracy use cutting-edge equipment and methods to work with these materials. Intricate components and parts can be manufactured quickly and to exact specifications with the help of a team of qualified engineers and technicians. Precision CNC machining services offer a wide variety of materials to fulfill the varying needs of their customers in a variety of industries like aerospace, automotive, medical, and more.

The Importance of Quality Control in CNC Machining Services for Maintaining Consistency and Accuracy

In order to guarantee both precision and consistency in the finished products, quality control plays a crucial part in Precision CNC machining services. Manufacturers can reduce the number of mistakes and improve the quality of the components they provide to customers by adopting stringent checks and inspections at various points in the production process. Keeping an eye on the machining parameters and dimensional tolerances is only half the job; the other is inspecting the completed goods thoroughly with state-of-the-art metrology equipment. Regular calibration and maintenance of the equipment are also a part of quality control in precise CNC machining services. To ensure that their products consistently function as designed, manufacturers must implement rigorous quality control procedures. This improves not just the level of satisfaction among customers, but also the company's standing as a provider of excellent precision machining.

The Wall